Alternative Fuel handling (AFR Cement Co-Processing)

Alternative Fuel handling (AFR Cement Co-Processing)

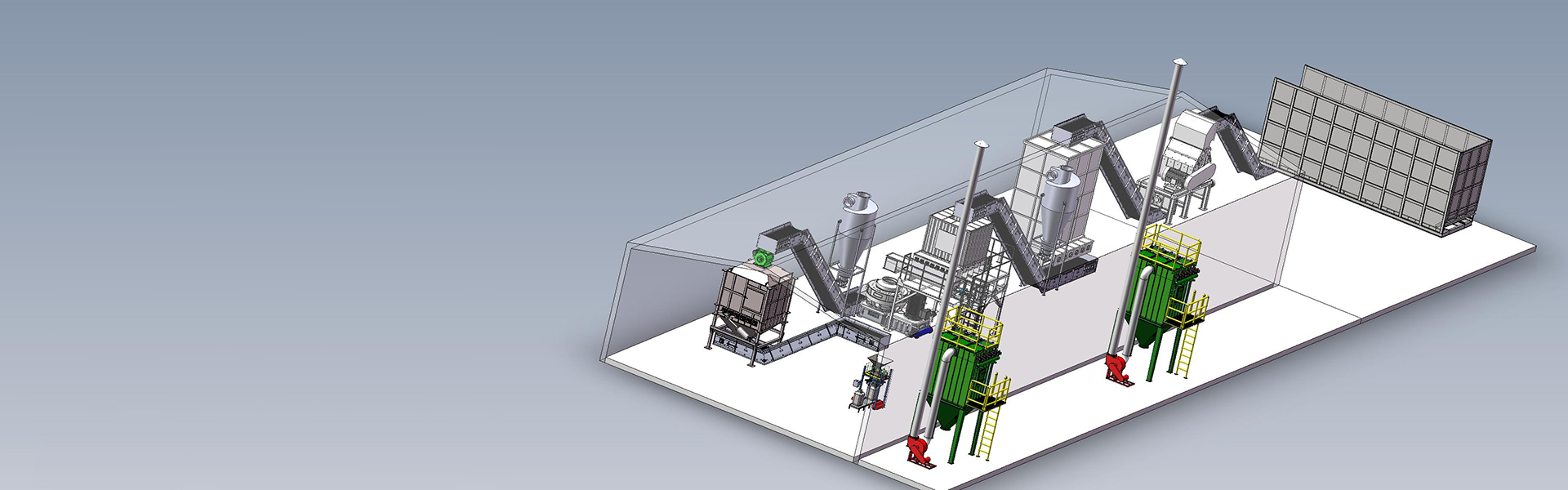

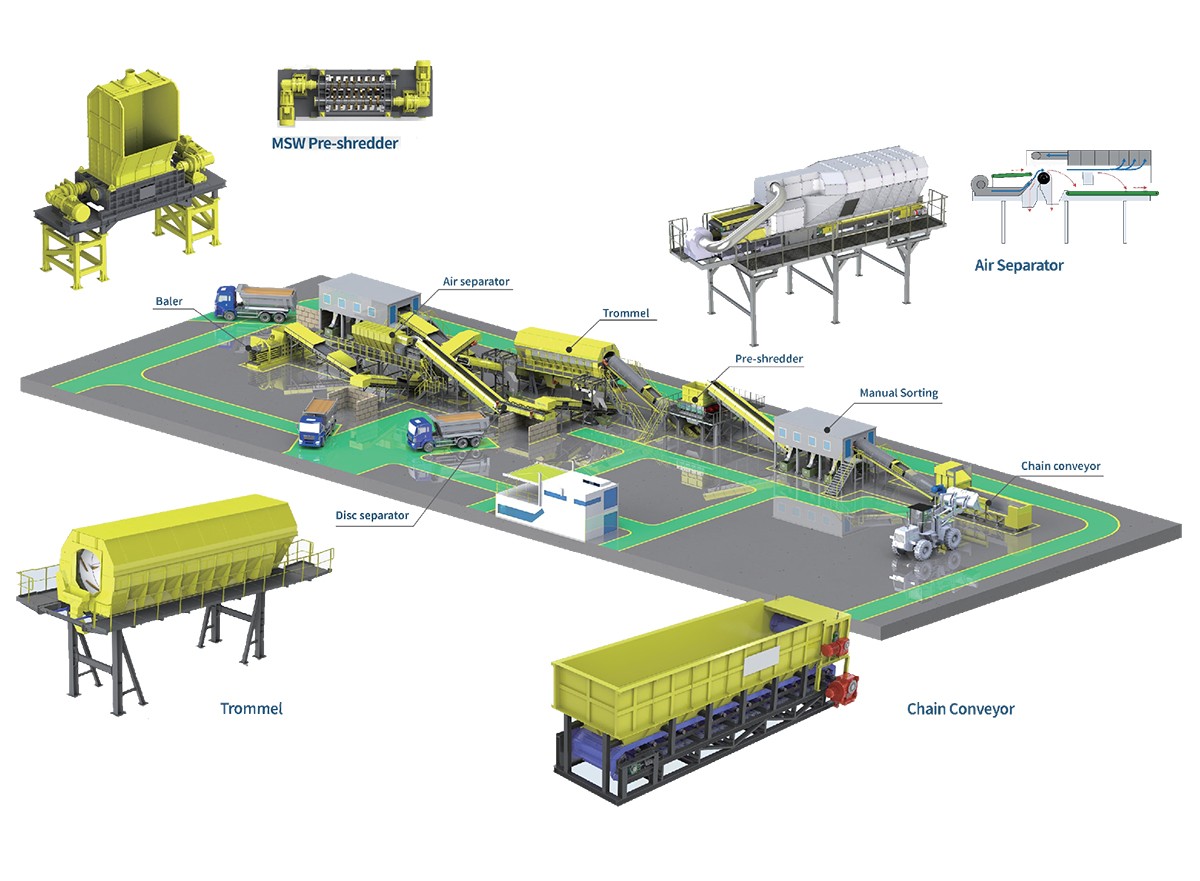

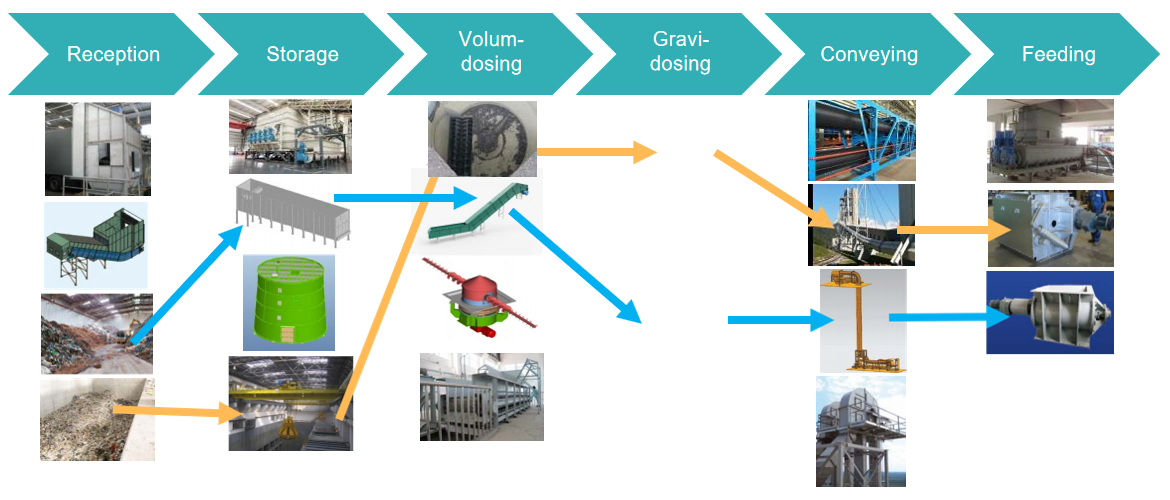

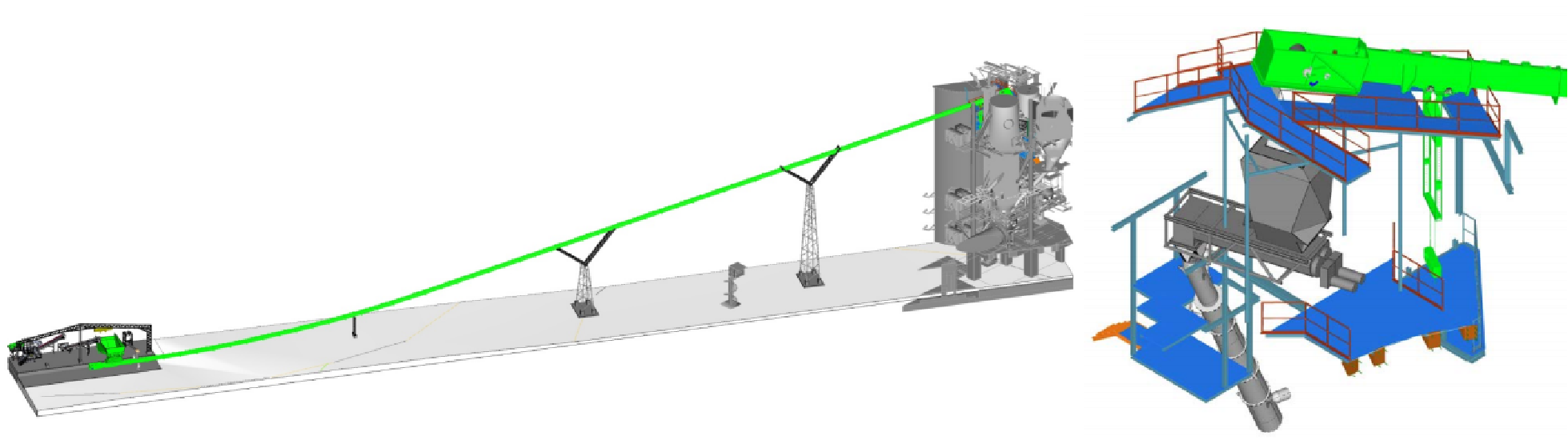

OPM offers the supply of turnkey plants for the AFR Cement Co-Processing production line. including the following steps:

a. RDF Pellets Production line

· Four Shaft Shredder

· Dewatering Screw Press .

· RDF pellet mills

· AFR feeding System

b. Hydraulic Baler Production line

· Hydraulic Baler

· AFR feeding System

Equipment List

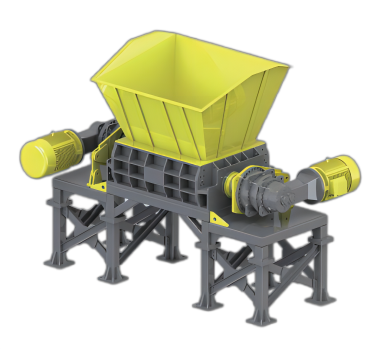

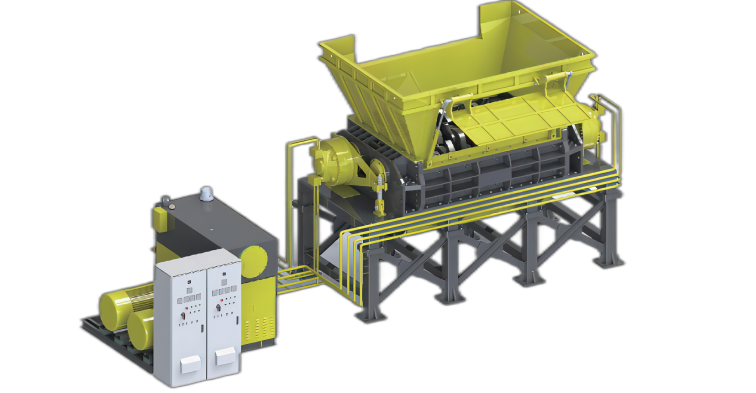

Double Shaft Shear Shredder

Double shaft shredder can be used for shredding most of wastes,such as the municipal solid waste,

wood waste,waste tyre, metal drum,plastic,RDF,biomass,etc. High capacity and high torque.

Application:

MSW shredding

RDF shredding

Industry waste shredding

Particle size after shredding: 50-150mm

Drive:Electric motor or Hydraulic drive optional

| Model | BEKEN-DS-2180 | BEKEN-DS-32120 | BEKEN-DS-40160 | BEKEN-DS-50180 | BEKEN-DS-61240 |

| A(mm) | 2760 | 2900 | 4180 | 5691 | 6400 |

| B(mm) | 1060 | 1850 | 2150 | 2160 | 2400 |

| C(mm) | 800 | 1200 | 1600 | 1800 | 2400 |

| D(mm) | 480 | 690 | 850 | 1120 | 1490 |

| H(mm) | 1850 | 2115 | 2530 | 3042 | 3330 |

| Cutter rotary diameter(mm) | φ284 | φ430 | φ514 | φ660 | φ800 |

| Shaft speed(rpm) | 14 | 15 | 11 | 23 | 7.5 |

| Cutter QTY(pcs) | 40 | 30 | 32 | 22 | 48 |

| Cutter thickness(mm) | 20 | 40 | 50 | 80 | 50 |

| Motor(KW) | 7.5+7.5 | 22+22 | 45+45 | 55+55 | 90+90 |

Technical Data Sheet

| Model OSK | OSK 75 | OSK220 | OSK315 | OSK510 | |

| Die | inside Diameter(mm) | 580 | 780 | 980 | 1250 |

| Capacity(T/H) | 0.8-1 | 3-4 | 5-6 | 9-11 | |

| Roller | Quantity | 3 | 3 | 4 | 6 |

| main motor | power(kw) | 75 | 220 | 315 | 510 |

| Feeder | motor(kw) | 1.5 | 2.2 | 3 | 5.5 |

| speed(rpm) | 500 | 500 | 500 | 500 | |

| outline dimension | mm | 2800x1200x1650 | 3200x1600x1800 | 3200x1700x2100 | 3530x1985x2075 |

| Weight | N.W | 4500kgs | 10000kg | 14390kgs | 21500kgs |

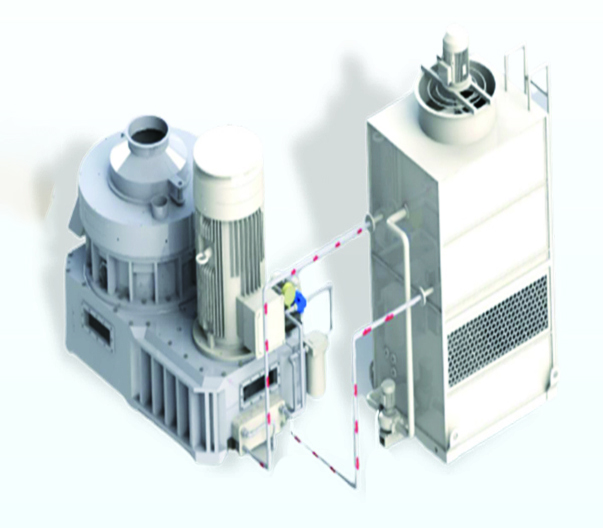

Main Features

1. Low Speed of Electric motor

High Torque from low speed will make sure good quality of pellets

2. External Cooling Tower make sure the long operation time each day (occassionally, 24/7 will be acceptable. )

3. Helical Gear box

Std of Accuracy of CNC machining same as Wind turbine gear box Grade 6, less than 0.8μm

4. Fully surrounded air will cool down the ring die and lower down the ash inside pellets.

5. No Bearing inside roller shell (underneath)

Unique patent design, save huge cost of grease and bearing and shorten the breakdown time

6. Innovated bearing system for pellet cutter low down the noise and vibration of pellet mill

7. Several Glass Viewing Window visualize the lubrication system inside the pellet mill.

8. 13 Years experience to develop biomass pellet mill.

9. Local team for after sales technical support.

10. Deploy new technology for production line and consumable parts.

11. Customized design and build

12. Hands on plant operation experience.

13. Monthly Capacity for our pellet mill is at least 30% higher than any other brands of pellet mill with sameoutput ofeletric motor (Energy is saved by 30%)

14. Monthly cost of spare parts (bearing/grease), since we do not have consumption of bearing and grease, the operational cost is only the ring die and roller shell oil seal, aramid packing, etc. Only 1/3-1/2 ofthe the other brands. (refer to the bar chart for consumption of bearing/ grease and service time of roller shell/die )

15. Monthly profit will be higher than other brands of pellet mill of same output.

Horizontal Full-Automatic Balers

| Model | Hydraulic Power ( Ton ) | Bale Size ( W*H"L ) mm | Feed Opening Size ( L*W ) mm | Bale Density ( kg/m3 ) | Bak Lines | Output ( Ton/hr ) | Power ( KW/HP ) | Machine Size ( L*W*H ) mm | Machine Weight ( Ton ) |

| OPW30QT | 30 | 500*500*(300-1000 ) | 950*500 | 250-300 | 3 | 1-1.5 | 2001/11/15 | 5000*2830*1800 | 4 |

| OPW40QT | 40 | 720*720*(300-1500) | 1150*720 | 350-450 | 4 | 1.5-2.5 | 15/20 | 6500*3190*2100 | 6.5 |

| OPW40QT-P | 40 | 720*800*(300-1500) | 1350*720 | 350-450 | 1 | 2001/2/3 | 18.5/25 | 6600*3300*2200 | 7 |

| OPW60QT | 60 | 750*850*(300-1600) | 1350*750 | 400-500 | 4 | 2001/3/4 | 22/30 | 6650*3300*2200 | 8 |

| OPW60QT-P | 60 | 1000*800*(300-1600) | 1500*1000 | 400-500 | 4 | 2001/3/6 | 30/40 | 6970*3450*2200 | 9.5 |

| OPW80QT | 80 | 1100*800 *(300-1800) | 1650*1100 | 450-550 | 1 | 2001/4/7 | 37/50 | 7900*3500*2300 | 11 |

| OPW80QT-P | 80 | 1100*900*(300-1800) | 1800*1100 | 450-550 | 4 | 2001/5/8 | 48.5/65 | 8100*3800*2200 | 12 |

| OPW100QT | 100 | 1100*1000*(300-2000) | 1800*1100 | 500-600 | 2001/6/10 | 55/75 | 8900*4050*2400 | 13.5 | |

| OPW100QT-₽ | 100 | 1100*1100*(300-2000) | 2000*1100 | 500-600 | 4 | 2001/7/11 | 60/80 | 9300*4080*2400 | 15 |

| OPW120QT | 120 | 1100*1100*(300-2100) | 2000*1100 | 550-650 | 5 | 2001/8/13 | 67/90 | 9700*4330*2400 | 17 |

| OPW120QT-P | 120 | 1100*1250*(300-2100) | 2200*1100 | 550-650 | 5 | 2001/9/14 | 85/115 | 9100*4350*2400 | 18 |

| OPW150QT | 150 | 1100*1100*(300-2100) | 2200*1100 | 600-750 | 5 | 2001/10/16 | 93/124 | 10000*4250*2500 | 20 |

| OPW150QT-P | 150 | 1100*1250*(300-2100) | 2400*1100 | 600-750 | 5 | 2001/12/18 | 101/135 | 10200*4370*2600 | 22 |

| OPW200QT | 200 | 1100*1100*(300-2100) | 2400*1100 | 700-850 | 5 | 14-20 | 111/148 | 10200*4370*2500 | 30 |

| OPW200QT-P | 200 | 1100*1250*(300-2100) | 2600*1100 | 700-850 | 5 | 15-22 | 121/161 | 11400*4370*2600 | 32 |

| OPW250QT | 250 | 1100*1250*(300-2100) | 2800*1100 | 850-1000 | 5 | 16-25 | 146/195 | 12300*4468*2600 | 35 |

Success Cases

Application scenarios

OPPS GROUP devotes the comprehensive application of Solid-Waste Database, Databeyond Cloud, Multi-sensor skils.

Machinery-design and control system, also the Al recognition technology to the waste and recycling industry

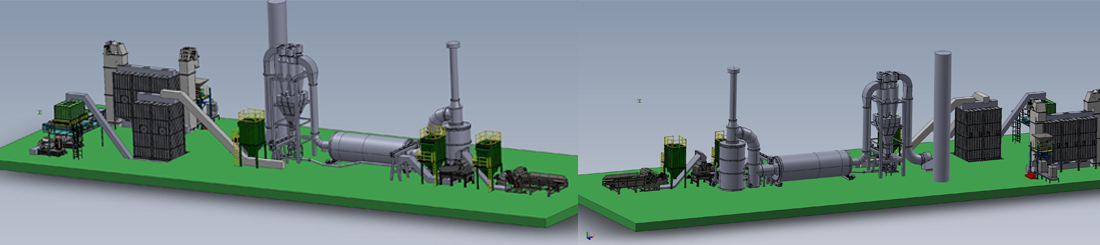

Cement co-processing

OPM Advanced Technology

-No shed design

-No labor design -Modular design

-Dust free design

-No truss, no walkway, no rain cover

-No roller design

-Low power consumption

-High accuracy

-Fully enclosed, Dust free

-Auto calibration

-Airlock design

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.