Membrane Separators for biogas upgrading

Membrane Separators for biogas upgrading

Biogas purification with membrane technology - achieving the highest possible methane yield through membranes with high separation efficiency.

At the core of our biogas upgrading system lies membrane technology. In addition to biogas upgrading, OPM can also provide technology for landfill gas upgrading. Biogas upgrading makes use of membrane technology whereas landfill gas upgrading makes use of membrane technology in combination with PSA technology. All upgrading systems benefit from the add-on of a CO2 Liquefaction technology. This enhances CO2 recovery, further improving the Carbon intensity (CI) score.

* OPM Straw-oriented Pellet Mills

Combine milling and pelletizing, suitable for 30% moisture of raw wheat straws, paddy straws, etc.

Reduce size of straws from 30-50mm to 2-3mm, biogas harvest will be arised by 11%.

* OPM Powerful Steam Explosion Reactor

Shorten the fermentation time of raw biomass from 28 days to 3-7 days, the scale of investment of AD tank can be reduced by 90%, only 10% of investment of existing AD tank.

* OPM Three stages of Membrane biogas upgrading plants

Combine H2S clean and biogas purification units into 40ft container as mobile unit, C02 content of final biogas output will be less than 2%.

Equipment List

Upgrading technology

At the core of our biogas upgrading system lies membrane technology. In addition to biogas upgrading, OPM can also provide technology for landfill gas upgrading. Biogas upgrading makes use of membrane technology whereas landfill gas upgrading makes use of membrane technology in combination with PSA technology. All upgrading systems benefit from the add-on of a CO2 Liquefaction technology. This enhances CO2 recovery, further improving the Carbon intensity (CI) score.

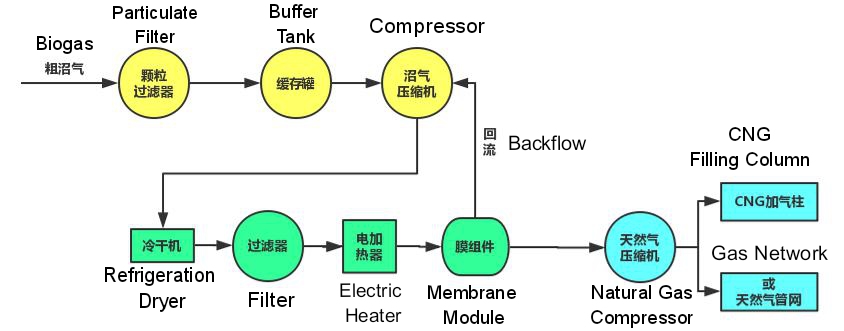

Process steps

How does it work?

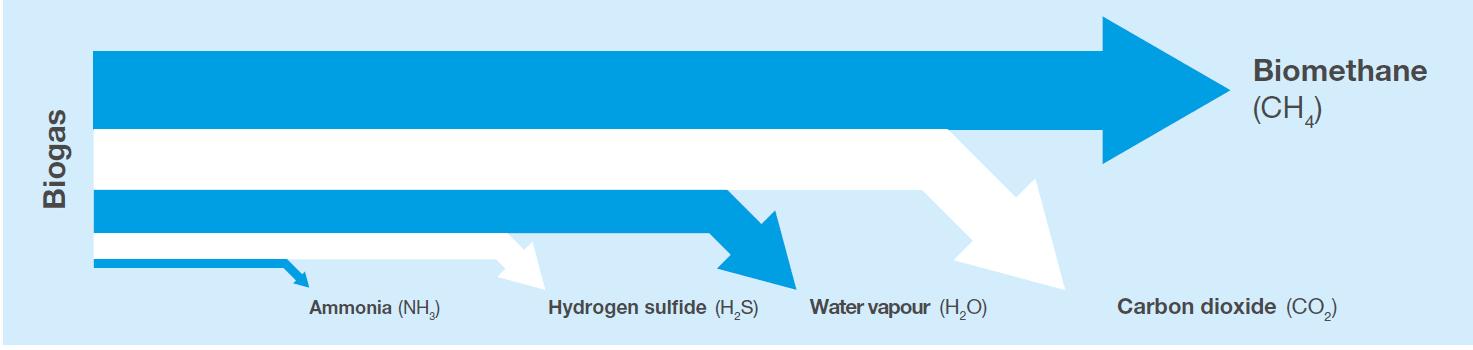

1. Cooling. The biogas first enters the pre-treatment system where moisture (biogas cooling) and contaminations, such as H2S, are filtered out.

2. Filtration. In the filtration step, the gas reaches filtering. This is done in the three filters filled with activated carbon. Two of these vessels contain active carbon for the removal of toxic hydrogen sulfide (H2S). The other vessel removes volatile organic compounds (VOCs).

3. Compression. After that, the gas is compressed to reach the required pressure before entering the membrane system. The heat of the drying of the biogas, from the compressor, and from the cooling can be recovered.

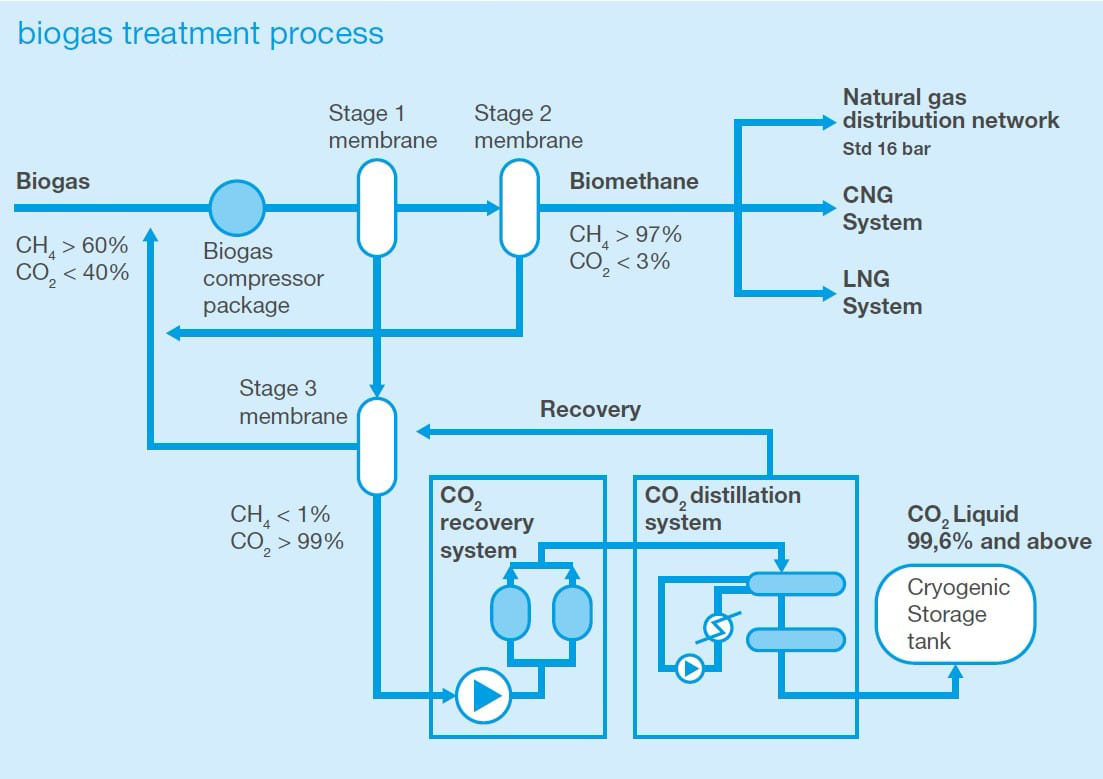

4. 3-stage membrane separation. The remaining gases after the pre-treatment include CH4 and CO2. The compressed gas mix flows through the 3-stage membrane system where the CO2 and CH4 are separated. The CO2 from this separation process can be recovered and liquefied.

5. Post-treatment. In the after-treatment system, the produced biomethane is analyzed and checked if all specifications are fulfilled. Also, THT is added that gives the biomethane an odorant.

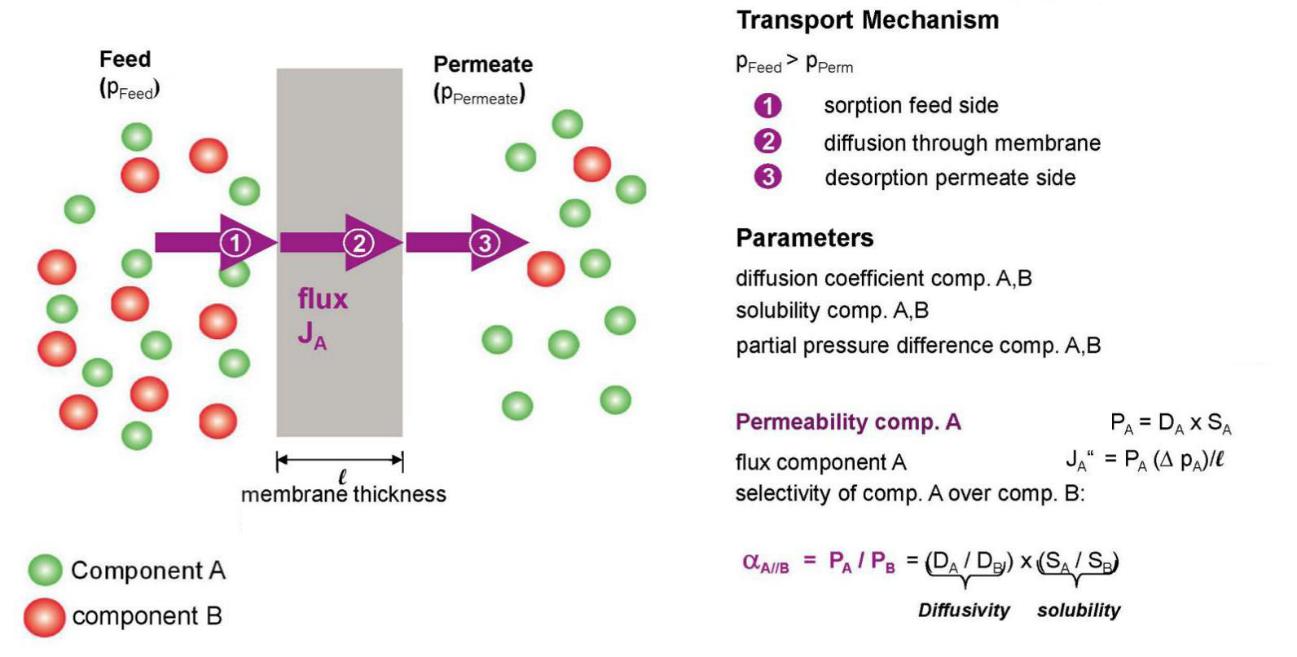

Membrane technology

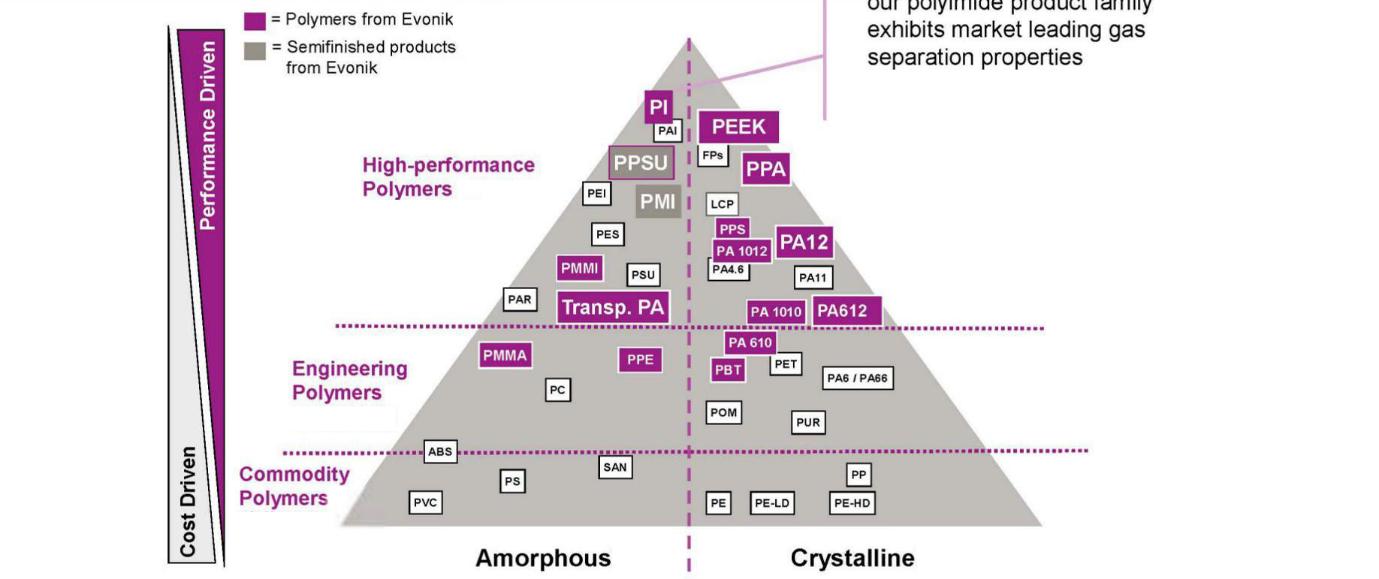

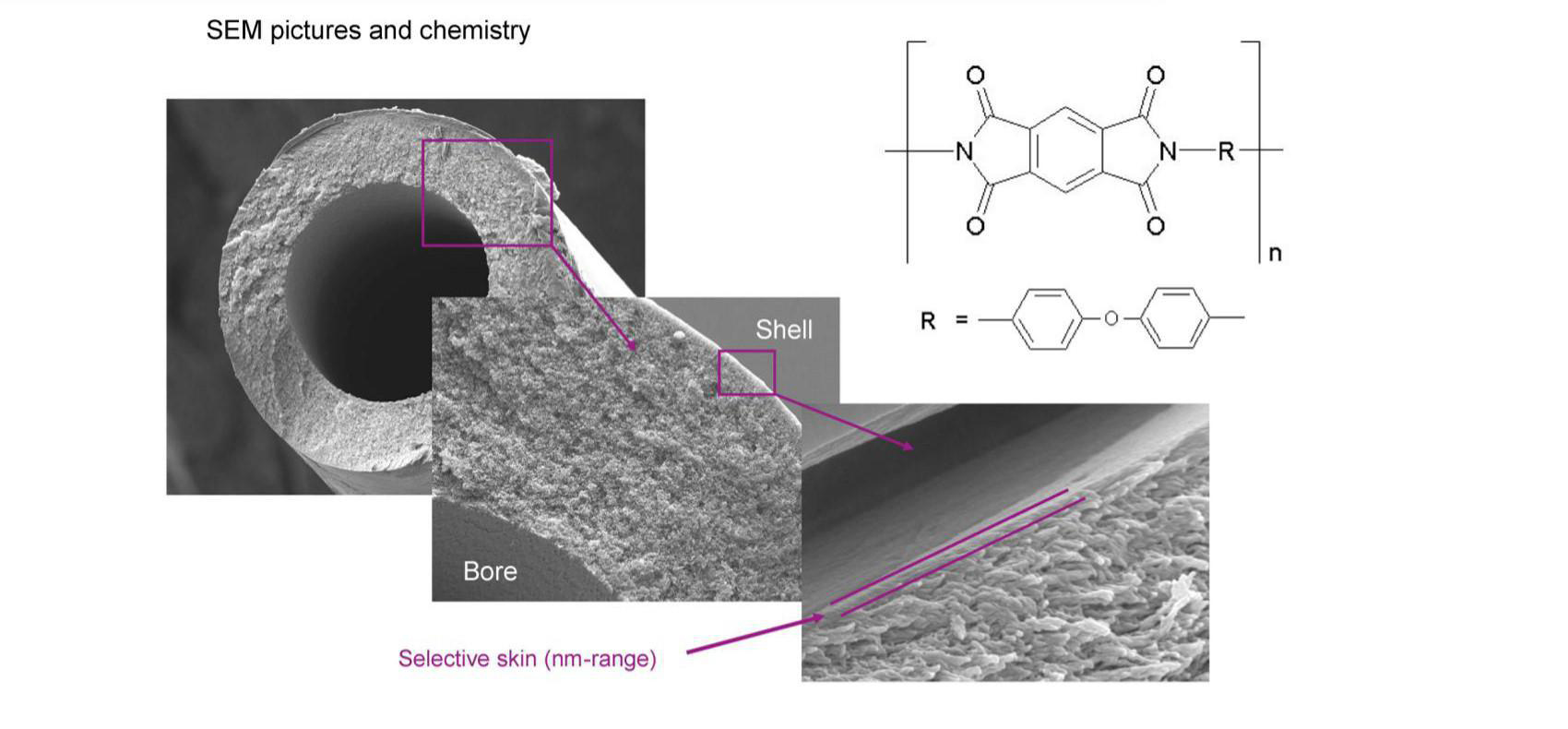

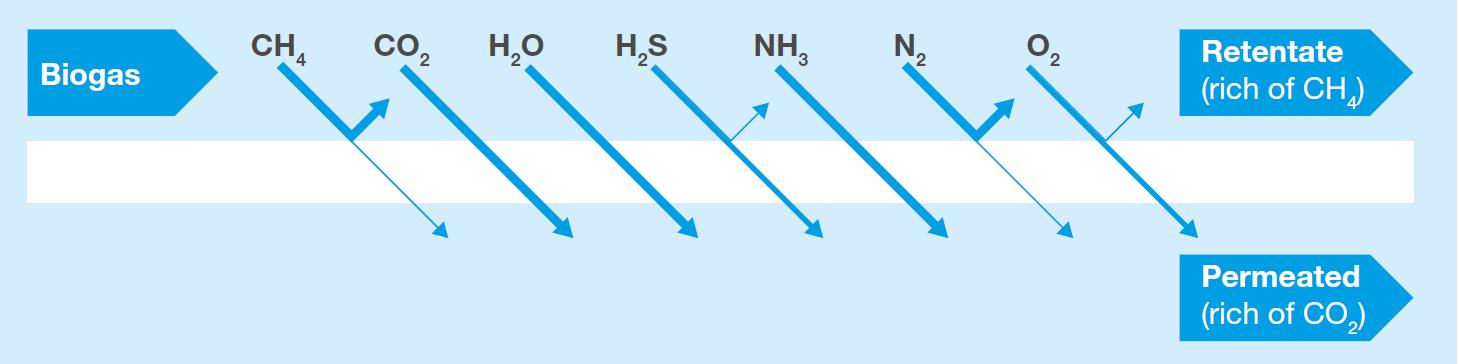

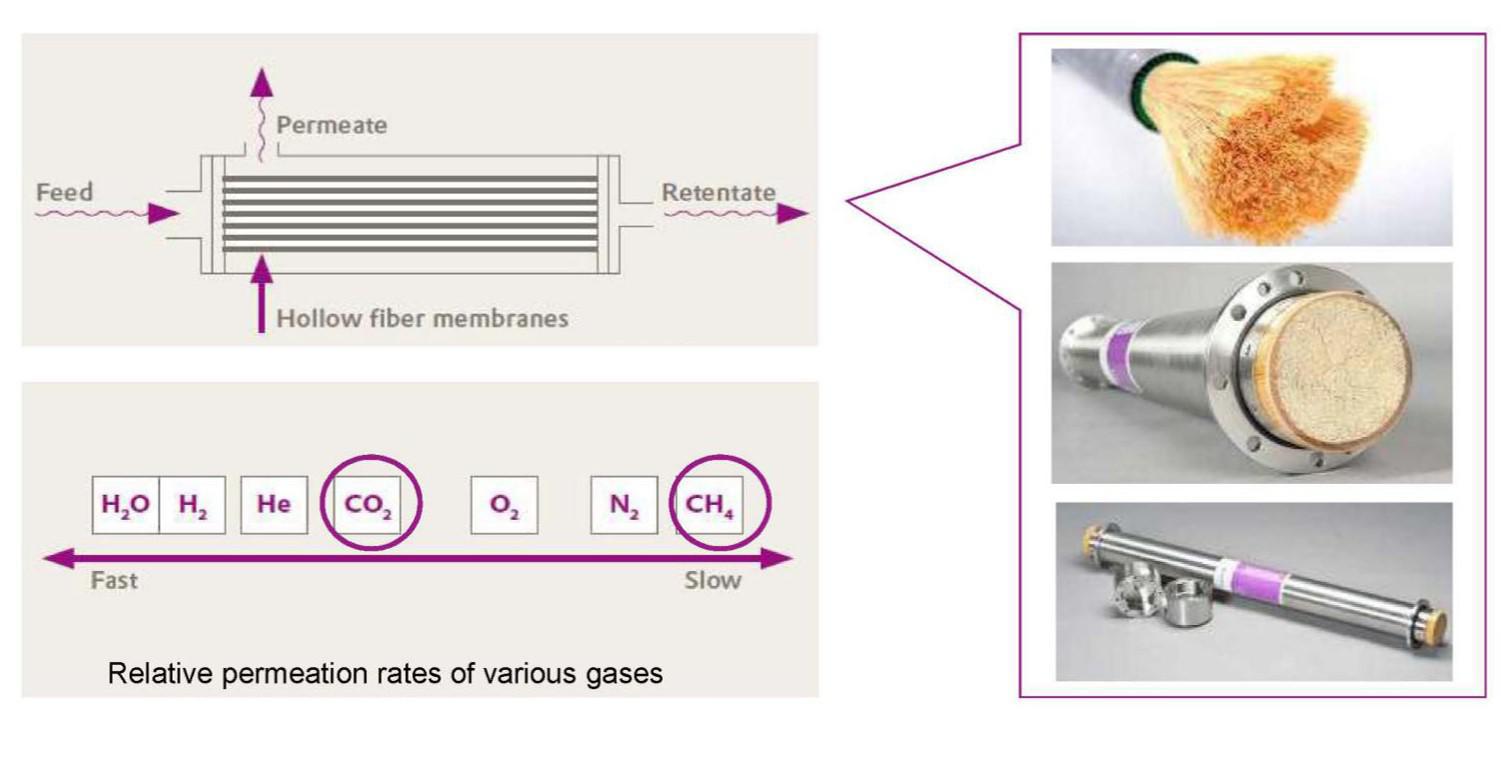

After the gas treatment, clean biogas consists mainly of CH4 (methane) and CO2 (carbon dioxide). The gas flows through the 3-stage membrane technology where the CO2 is separated from the methane. The CO2-stream can be recovered and liquefied with our CO2 liquefaction technology. For the separation of carbon dioxide from biogas, OPM uses membranes with the highest selectivity available in the market for example Air Products – as they pass CO2 more efficiently and quickly than methane. Membranes with high separation efficiency, enable the maximization of renewable natural gas yield. Depending on the grid or user requirements, the gas can be purified to the preferred methane concentration

The separation between the biogas and chemicals is facilitated through a three-stage membrane arrangement. In the first stages, the biggest separation between the CO2 and the raw biogas transpires. In the second membrane stage, the RNG reaches its desired purity. The third stage enables the achievement of maximum methane recovery. Through this patented design, the gas from the first and second stages is recirculated to obtain the highest efficiency and minimal methane loss (≤ 0.5%). This is a significantly lower methane slip value compared to other biogas purification technologies.

Biogas-Upgrading Membrane Plants

OPM is an EPC supplier of different brands of Ultra-high selectivity polymeric refinement membranes OPM combines this technology with well-engineered balance of plant including quality containers and control systems.

The biogas upgrading plants developed and industrialised by OPM make it possible to obtain high levels of purity with recovery efficiency in excess of 99%, thus making the pure biomethane suitable for distribution in national gas networks or for use as a vehicle fuel.

Figure 1: Biogas upgrading process – purification of biomethane

Figure 2: Permeability of different gases through a biogas upgrading plant membrane

Figure 3: OPM’s membrane-based biogas upgrading plant treatment process diagram

Biogas-Upgrading Membrane Plant Features

* System operates at high pressure

* CO2 is easily recoverable near eliminating methane slip (loss)

* The system is simple, innovative and modular

* The delivery pressure of biomethane is from 10-20 bar with a biogas input flow rate from 50-3,000 Nm3/h

Selective solvents for CO2 such as amines are an established method of separating acidic gases from various types of gas including flue gas, biogas and syngas. OPM have experience of this technology type which may be deemed as desirable for our customers. Contrasting to membranes, selective solvents operate at low pressure and require heat to regenerate. It is possible that this heat is derived from the surplus heat from a gas engine CHP plant. The levels of separation achieved are high. Selective solvent plants are also ideal for use in situations where network injection occurs at low pressure.

High performance

The plant technology is based on the use of a dedicated solvent enriched with specific additives suitable for the treatment of biogas, that also allow the removal of CO2 without any special pre-treatment process.

The biomethane obtained by this process is of extremely high purity (more than 99%). With respect to traditional amines, solvent consumption is far lower.

Key benefits

* High reliability and availability

* Low power consumption

* Low operating costs and optimized TCO

* Full range of services and maintenance

* Modular units (extension of the

biogas treatment capacity)

* Simple and quick installation

* Small footprint

* Biomethane injection into the

low pressure or high pressure

network

Additional modules:

* Biomethane liquefiers

* CO2 liquefiers

Related services

* Preventive and curative

maintenance

* Remote maintenance

* Hotline 24/7

* Spare parts

* Operating support and expertise

* Training

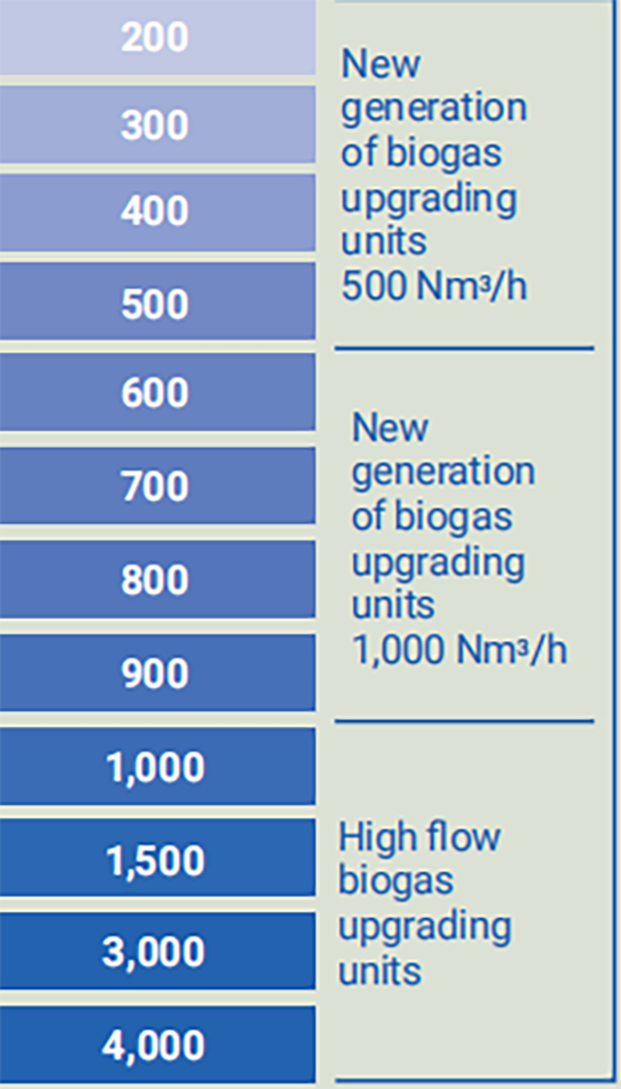

Biogas upgrading units range

Raw biogas treatment capacity (Nm3/h)

Our broad product range offers a solution to diverse project types, such as:

* Agricultural

* Waste water treatment

* Municipal solid wastes

* Biowastes

* Industrial & agroindustrial

* Multi feedstock

High performances:

* Methane recovery rate > 99.5%

* Electrical consumption < 0.27 to 0.31 kWh/Nm3 of biogas

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.