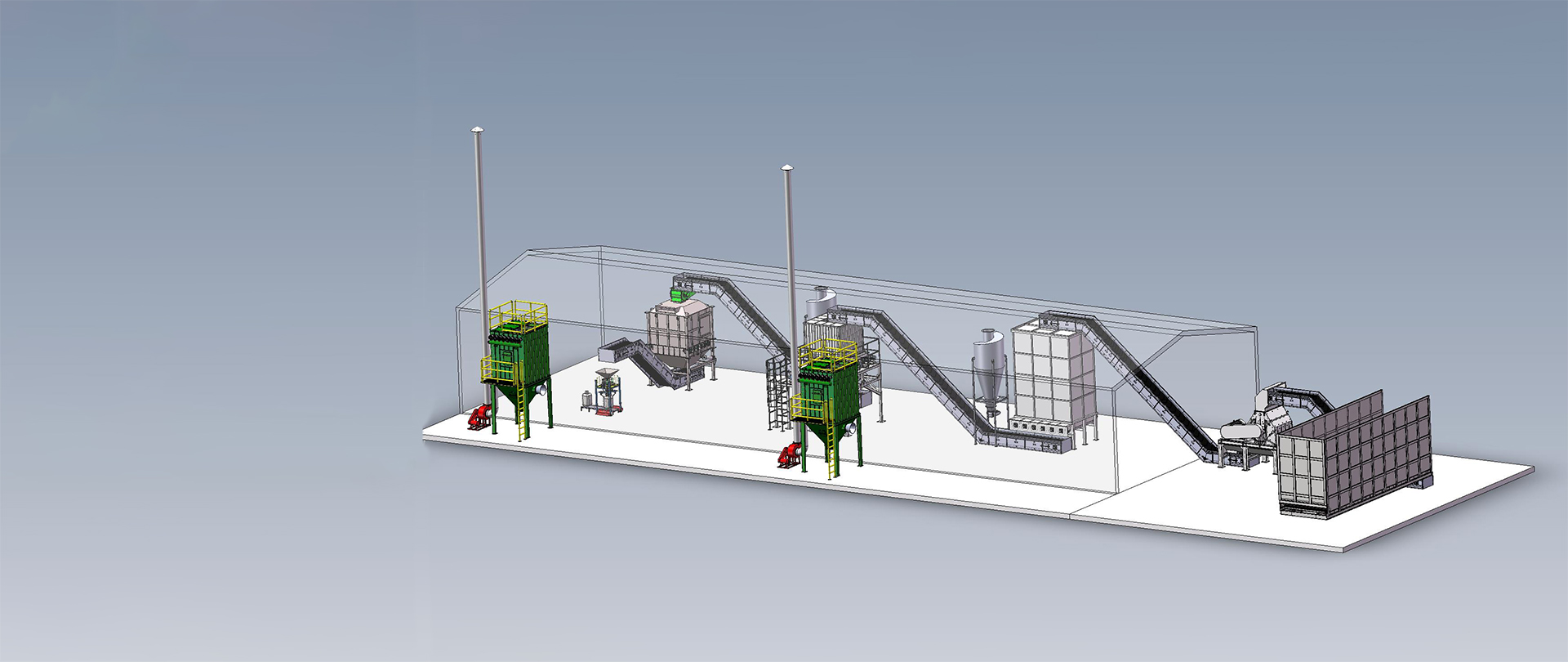

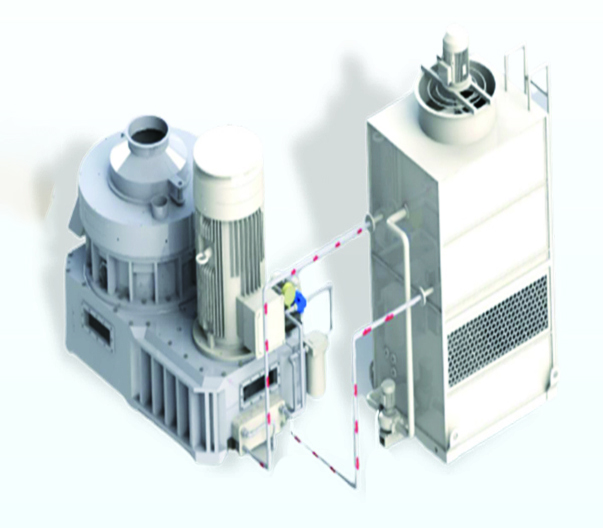

Black Pellets production line

Black Pellets production line

(Steam Explosion technology-EFB and Woody Material)

OPM offers the supply of turnkey plants for the production of black pellets production line

including the following steps:

a. Wood Black Pellets Production line

· Chipper

· Hammer Mills .

· Steam Explosion reactor

· Single Pass Dryer

· Wood Pellet mills

b. EFB Black Pellets Production line

· Shredder

· Steam Explosion reactor

· Low temperature Single Pass Dryer or mesh dryer.

· EFB Pellet mills

Equipment List

Chipper

220KW 15-20T/H (Log <=30cm)

Rotor diameter:1000mm

Rotor Speed:550rpm

Capacity:75m3/H

Feeding size:330mm*1050mm

Number of rotor knives:4*2 pcs

Feeding Speed:37m/min

Main drive motor power:220KW

Feeding power(frequency):7.5KW+7.5KW

Hydraulic oil pump motor:2.2KW

Finished Chip length(mm):15mm

Outline Dimension (mm):9640x3500x1500mm

Hammer Mill

Main drive motor power:180KW

Feeding Belt Conveyor:4KW

Capacity:5-7t/h

Hammer Qty:100

Hammer Material:High Mn Steel

Hammer Life Time:3-5 months

Rotor Rotation:2000

Static Knives:4 PCS

Cyclone:1800MM

Fan(Positive):18.5KW

Dust Collector:30

Air Lock(BF-650):3KW

Output Belt Conveyor:4KW

Gross Weight:5.6T

Overall Dimension:2500*2700*3100mm

Drying System

SK-40 Three Pass Rotary Drum Dryer System

(Moisture of Dust:45% or less ,Final Moisture:15% roughly)

5-6T/H Three pass drum dryer

Include:

Part 1:

Feed Screw 4kw 1set

Three pass drum Φ3200x13000mm with Heat insulation layer、roller support,etc

Screw plate 1 set

Support roller、bearing、shaft 4 sets

Frame support 2 sets

Main Trasmission motor 5.5KW 4 sets

Seal device,inspection door 1 set

Auxillary equipment 1 set

Part 2: Pipe system

Head of Furnace 1 set

End of Furnace 1 set

Induction Fan 90KW

Cyclone seperator 2 sets

Dust bin 1 set

Air Lock 4KW 2 set

Air Pipe 1 set

Flange of pipe 1 set

Eletric system with Temperature alarm lock system

Hot air system-Burner Saw dust as fuel

Automatic feed back from the out put of the dryer to the heating burner without human interfere

Rotary seive 2,2KW 1set

Belt Conveyor 2.2KW 1set

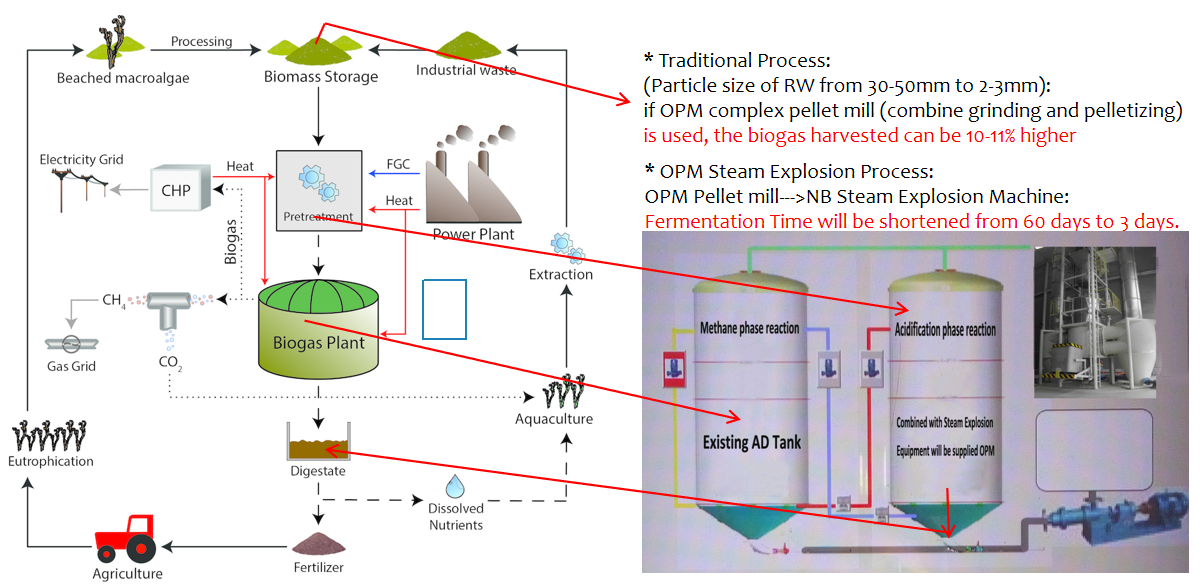

Principle Innovation

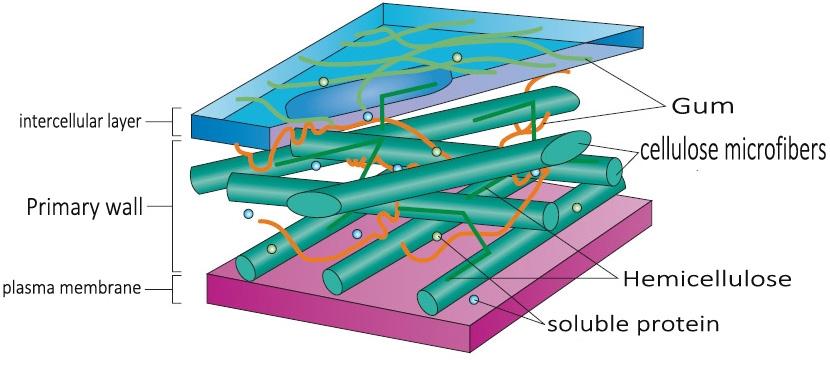

I. Biomass conversion barrier

* Conversion object: Organic cell body

* Barrier No.1: Three Layer Wrap for cell.

* Barrier No.2: crystal structure

* Other Barrier: cell wall, epidermis, waxy layer, etc

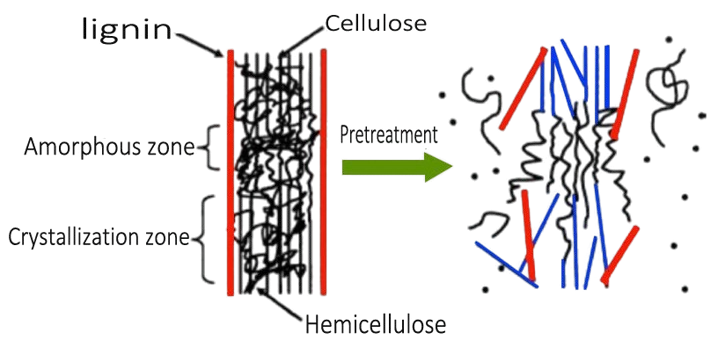

II. Pretreatment Mechanism

* Break the wall

* Three element separation

* Break down the structure

* Reduce crystallinity

* Increase porosity

* Improve accessibility

Core Technology

III. Supersonic instantaneous ejection steam explosion technology* Instantaneous ejection steam explosion (ICSE) technology is derived from the aircraft carrier aircraft accelerated take-off device

The burst speed reaches 0.00875 seconds

* The instantaneous blasting power reaches an astonishing 22MW, while foreign thermal spray tank technology is only 0.026MW;

* Ultimately, it is possible to instantly break the microstructure of biomass with low energy consumption, allowing it to be rapidly degraded;

* From principle innovation to equipment research and development, all are independent innovations, with independent and complete intellectual property rights.

Essential changes in biomass

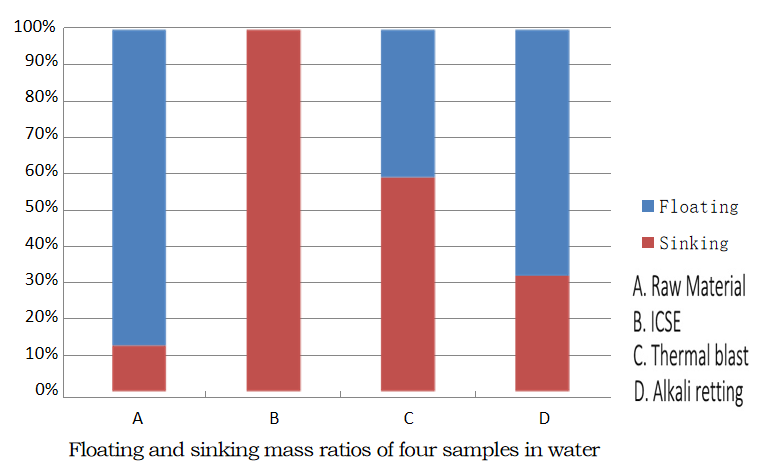

VI. Sedimentation characteristics* All ICSE sinks to achieve complete miscibility with water.

* The thermal blast from Europe has sedimentation ratio is 0.592: 1.

* The alkali pile retting settlement ratio is 0.32: 1

* raw material alone sedimentation ratio 0.127:1

V. Hydrophilic/Hydrophobic Characteristic Index* ICSE is the only one among the four samples with a hydrophilic index greater than 5, indicating that the material characteristics have changed from hydrophobic to hydrophilic.

* The results are consistent with the measurement results of settlement characteristics, indicating that settlement characteristics are closely related to surface energy characteristics.

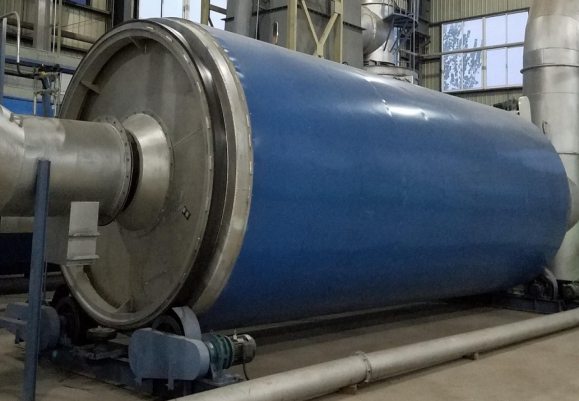

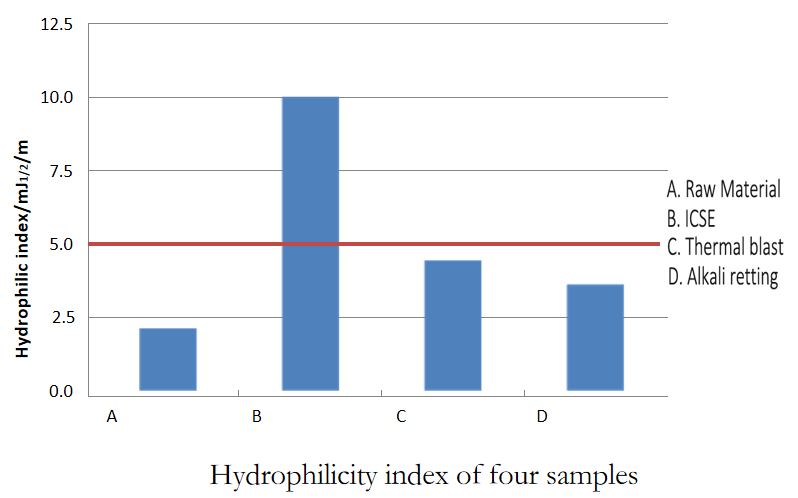

Steam Explosion Equipment

NB800, NB1500 and NB2000 series industrial application steam explosion devices have been used in many companies In terms of actual production, the application industry involves a variety of bio-based products such as fuel ethanol, butanol, xylitol, etc. Covering bioenergy, biofertilizer, biofeed, food processing, biopharmaceuticals, waste treatment, etc.field . The NB2000 series of large-scale instant ejection steam explosion machines has a single cylinder volume of 10 cubic meters and a single machine blasting power of more than 50MW, establishing the company and its technical team as an international leader in the field of steam explosion.

|  |  |

Advantage of OPM Steam Explosion

High Efficiency!

* The pretreated straw is in the form of a slurry that is completely miscible with water, eliminating stratification and floating phenomena, and smoothly realizing the fluidized transportation and fermentation of pure straw;

* When the temperature of the exploded material is lower than 50℃, it can be directly put into fermentation; there will be no blockage or bridging problems in the discharge;

* The anaerobic fermentation degradation time of pretreated straw is shortened from 60 days to three days;

*Compared with thermal blast equipment, the material is sprayed in tens of seconds, resulting in the problem of inconsistent biochemical properties of "premature and late"

* The new technology increases the blasting speed by three orders of magnitude; the blasting power density increases by six orders of magnitude;

* The processing cycle is thus shortened from tens of minutes to 90 seconds, which greatly reduces the pretreatment energy consumption. The steam consumption per ton of material drops from 1 ton to 0.1 ton.

* At the same time, the fast pace of pretreatment has greatly improved the efficiency of the equipment, and the scale of land occupation and equipment investment have also been reduced by 20 times.

Long Life Span!

The key components have a fatigue strength that meets 100,000 blasts.

Big Capacity!

NB2000 allow 10m3 one cylinder

Thermal Blast :

400 units cylinder/project

OPM Steam Explosion :

20 units cylinder /project

Bio-Methane!

The key components have a fatigue strength that meets 100,000 blasts.

Technical Data Sheet

| Model OSK | OSK 75 | OSK220 | OSK315 | OSK510 | |

| Die | inside Diameter(mm) | 580 | 780 | 980 | 1250 |

| Capacity(T/H) | 0.8-1 | 3-4 | 5-6 | 9-11 | |

| Roller | Quantity | 3 | 3 | 4 | 6 |

| main motor | power(kw) | 75 | 220 | 315 | 510 |

| Feeder | motor(kw) | 1.5 | 2.2 | 3 | 5.5 |

| speed(rpm) | 500 | 500 | 500 | 500 | |

| outline dimension | mm | 2800x1200x1650 | 3200x1600x1800 | 3200x1700x2100 | 3530x1985x2075 |

| Weight | N.W | 4500kgs | 10000kg | 14390kgs | 21500kgs |

Main Features

1. Low Speed of Electric motor

High Torque from low speed will make sure good quality of pellets

2. External Cooling Tower make sure the long operation time each day (occassionally, 24/7 will be acceptable. )

3. Helical Gear box

Std of Accuracy of CNC machining same as Wind turbine gear box Grade 6, less than 0.8μm

4. Fully surrounded air will cool down the ring die and lower down the ash inside pellets.

5. No Bearing inside roller shell (underneath)

Unique patent design, save huge cost of grease and bearing and shorten the breakdown time

6. Innovated bearing system for pellet cutter low down the noise and vibration of pellet mill

7. Several Glass Viewing Window visualize the lubrication system inside the pellet mill.

8. 13 Years experience to develop biomass pellet mill.

9. Local team for after sales technical support.

10. Deploy new technology for production line and consumable parts.

11. Customized design and build

12. Hands on plant operation experience.

13. Monthly Capacity for our pellet mill is at least 30% higher than any other brands of pellet mill with sameoutput ofeletric motor (Energy is saved by 30%)

14. Monthly cost of spare parts (bearing/grease), since we do not have consumption of bearing and grease, the operational cost is only the ring die and roller shell oil seal, aramid packing, etc. Only 1/3-1/2 ofthe the other brands. (refer to the bar chart for consumption of bearing/ grease and service time of roller shell/die )

15. Monthly profit will be higher than other brands of pellet mill of same output.

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.