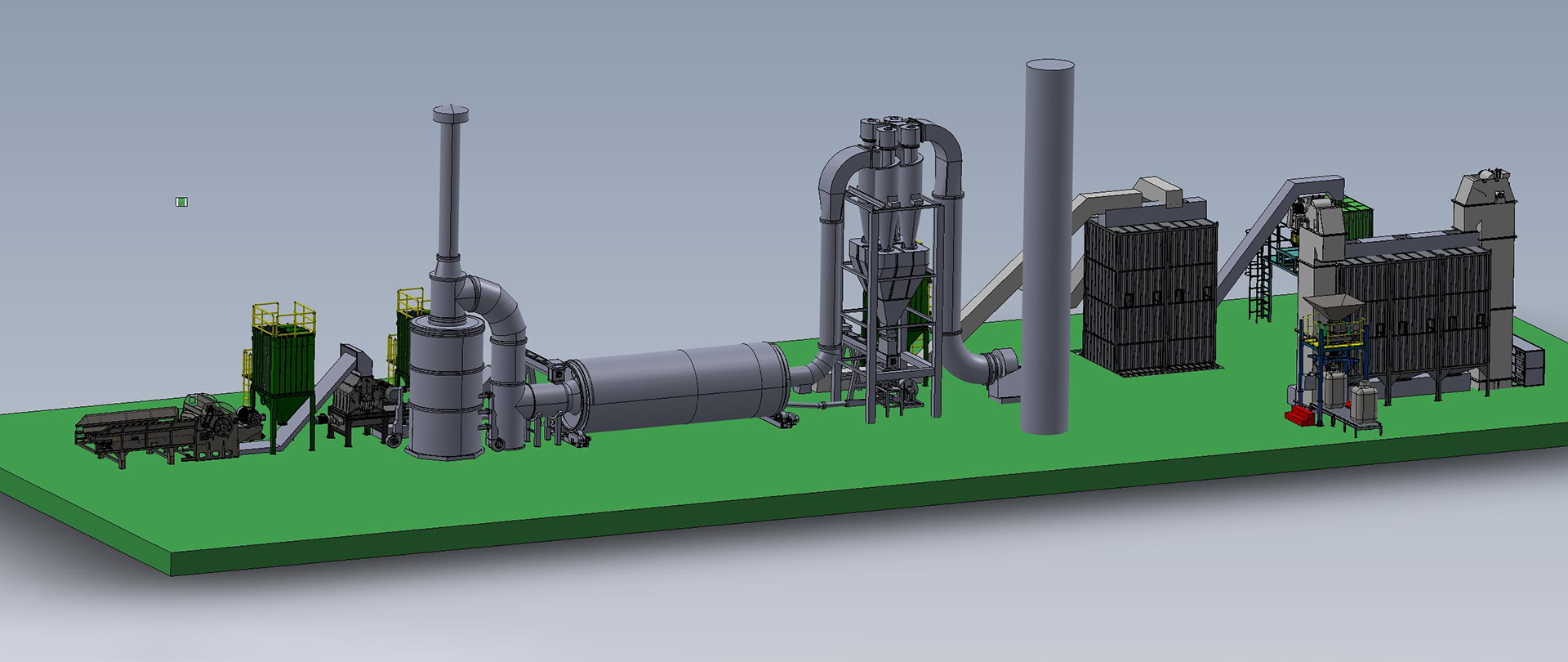

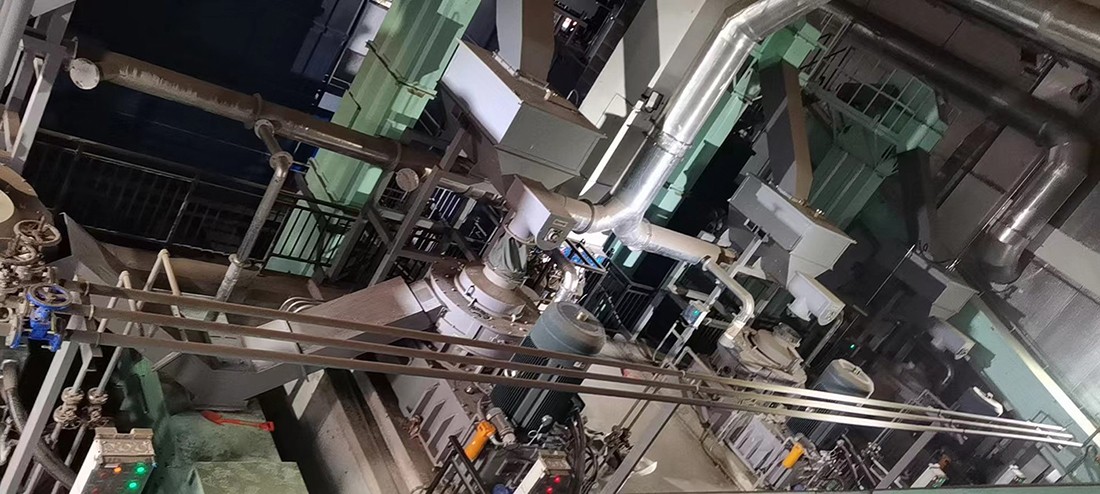

Sludge Pellets Production line

Sludge Pellets Production line

OPM offers the supply of turnkey plants for the production of Sludge pellets

including the following steps:

· MDS multi-disc Screw Press (or Filter Press)

· Low Temperature Mesh Dryer for sludge drying

· Hammer mills for sludge

· Sludge Pellet mills

· Sludge pellets Gasifier for CHP application

Equipment List

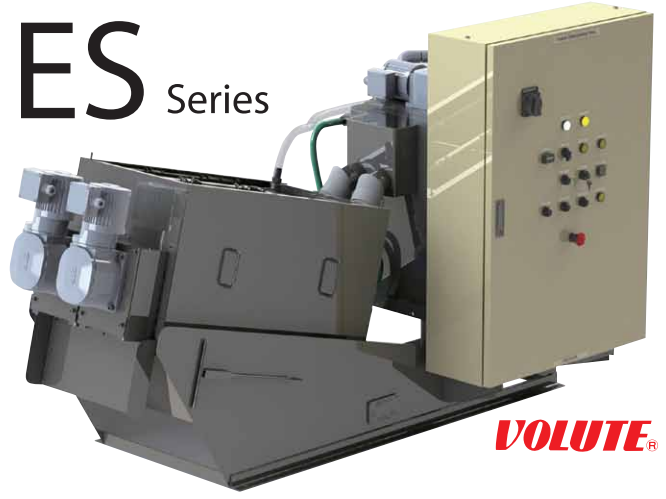

VOLUTE Brochure

Sludge Dewatering Press Volute

ES series comprises of models with basic functions at affordable price and are recommended for entry models. ES series lineup also includes models capable of handling large amount of sludge.

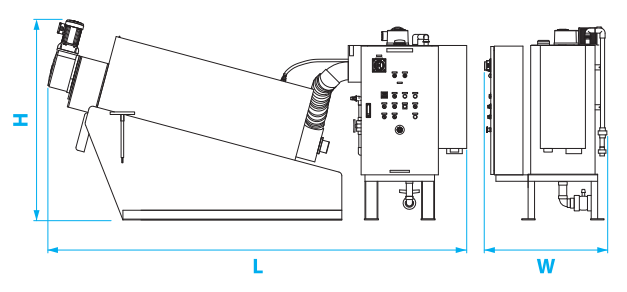

Specifcations List

| Model | Dimensions(mm) | Total Power Consumption(kW) | Weight(kg) | |||

| L | W | H | Empty | Operation | ||

| ES-051 | 1095 | 738 | 850 | 0.2 | 155 | 175 |

| ES-101 | 1831 | 722 | 1180 | 0.2 | 240 | 330 |

| ES-131 | 1974 | 722 | 1180 | 0.2 | 260 | 355 |

| ES-132 | 2059 | 890 | 1180 | 0.3 | 340 | 485 |

| ES-201 | 2548 | 879 | 1389 | 0.3 | 325 | 475 |

| ES-202 | 2548 | 1410 | 1389 | 0.73 | 665 | 885 |

| ES-301F | 3292 | 970 | 1678 | 0.74 | 855 | 1145 |

| ES-302F | 3492 | 1250 | 1678 | 1.11 | 1310 | 1990 |

| ES-303F | 3641 | 1596 | 1678 | 1.86 | 1805 | 2775 |

| ES-351 | 3859 | 1160 | 2247 | 1.87 | 1570 | 2170 |

| ES-352 | 4159 | 1550 | 2247 | 3.75 | 2660 | 3610 |

| ES-353 | 4424 | 2100 | 2247 | 6 | 3870 | 5370 |

| ES-354 | 4944 | 3164 | 2260 | 8.2 | 5560 | 8160 |

*The above foures are for models with one chemicalinlet, We also have models with two chemical inlets , o please contact us for detalis

*Specifcations are subject to change without notice, for updated technical infomation, please contact us.

Layout Drawings

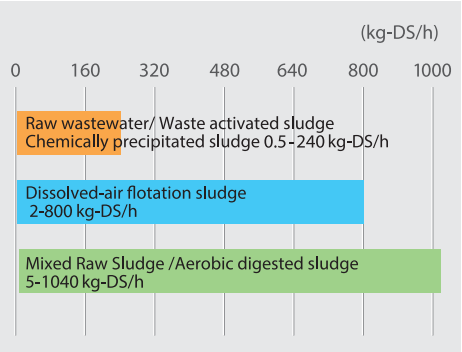

Throughput Range

Filter Press

· In 2011,the filter press was developped and tested, and launch to the market since 2014.

· Good Sealing Effect

· Easy and safe handling of filter cloth

· Reduce the water content, the air blows through the cake (No air leakage)

· Water content of filter cake of copperr concentrate and gold concentrate, etc. Non ferrous concentrate is less than 8%.

· In other industries, the water content in the same working condition will be reduced by 8% to 15%), the filter cake can fall off automatically thus the comprehensive operation costs can be reduced.

· Uniform feeding, no uneven thickness of filter cake

· Complete and thorough washing can save 30%-50% of water

· Compared with the filter plate of other manufactured, optimized filter plate will have 13% wider filter area.

· Backblow pipe and feed pipe are clean and without residual slurry, and service life of backblow valve can be double.

· High intelligent automatical operation coupled with cake-taken off machine, the discharging of cake will be 4-5 times each hour because new type of filter cloth is 60% faster than previous design.

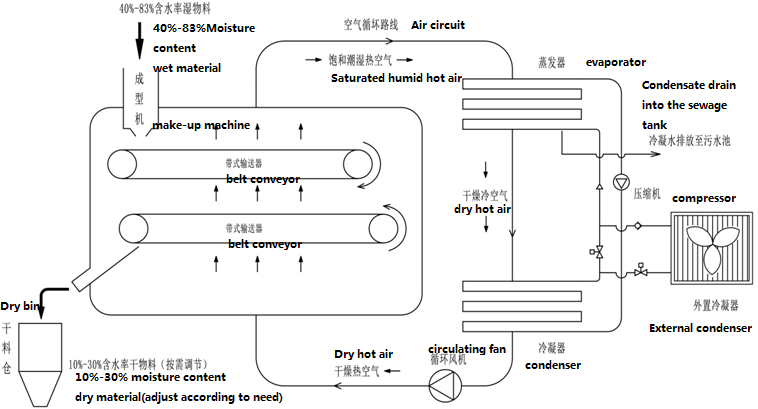

Closed Cold Filter Cake Dryer

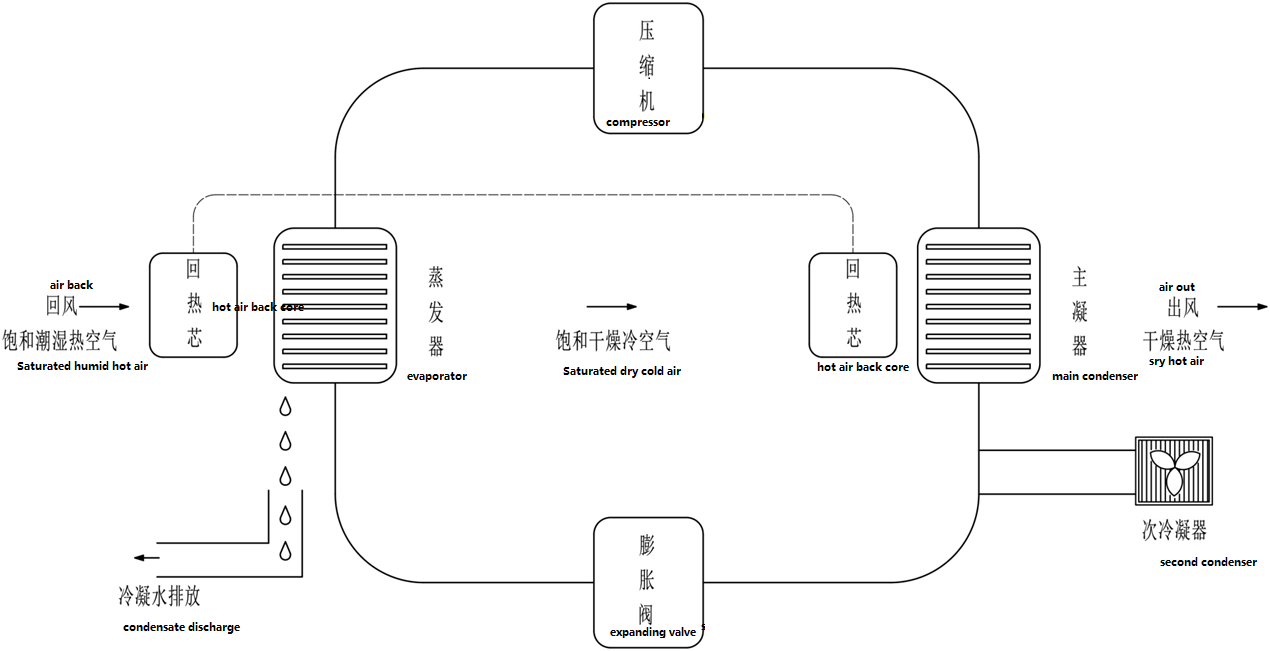

Cold drying principle

The closed cold filter cake dryer developed by us ,using low temperature evaporation and condensation dehumidification principle, adopts convective hot air to dry the high moisture content material on the stainless steel net belt and then using the wet hot air being cooled by condensation and water removal process to achieve the purpose of drying and reducing the material. The whole machine adopts the fully enclosed modular design and the drying process has no thermal damage.

Low temperature drying and condensation dehumidification principle

The system ues air energy to cool the hot wet air from the drying oven , and the cool dry air is reheated and sent back to the drying oven. During dewatering, the latent heat of moisture condensation is recycled so as to fully recycle the energy provided by air energy systems.

System Features

cake ≤10% moisture content, The material is reduced by more than 80%

Own strong drying and material reducing capacity, cake moisture≤ 10%~60%, can adjusted according to the customer request .The material can be reduced by more than 80%.

1:4.2 Dehumidification rate, Far exceed industry standard

Using super high efficiency dehumidification drying process, Dehydrating ability leads the world, Integrated dehumidification ratio is above 4.2kg.H2O/kw.h.

Heat is 100 per cent without thermal damage

Adopt closed system design + Heat recovery technique, Perfect heat utilization, No loss, high efficiency to use the system.

High performance heat preservation box body, heat is difficult to dissipate.

Perfect exceed continuous high temperature heat supply, dehumidification and heat removal of open drying equipment.

Technical Data Sheet

| Model OSK | OSK 75 | OSK220 | OSK315 | OSK510 | |

| Die | inside Diameter(mm) | 580 | 780 | 980 | 1250 |

| Capacity(T/H) | 0.8-1 | 3-4 | 5-6 | 9-11 | |

| Roller | Quantity | 3 | 3 | 4 | 6 |

| main motor | power(kw) | 75 | 220 | 315 | 510 |

| Feeder | motor(kw) | 1.5 | 2.2 | 3 | 5.5 |

| speed(rpm) | 500 | 500 | 500 | 500 | |

| outline dimension | mm | 2800x1200x1650 | 3200x1600x1800 | 3200x1700x2100 | 3530x1985x2075 |

| Weight | N.W | 4500kgs | 10000kg | 14390kgs | 21500kgs |

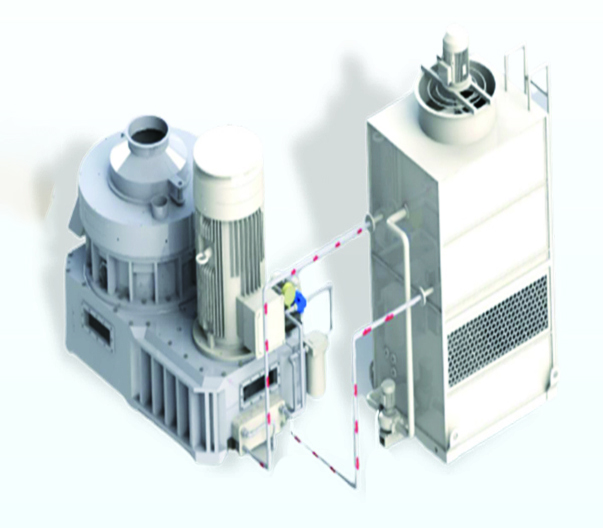

Main Features

1. Low Speed of Electric motor

High Torque from low speed will make sure good quality of pellets

2. External Cooling Tower make sure the long operation time each day (occassionally, 24/7 will be acceptable. )

3. Helical Gear box

Std of Accuracy of CNC machining same as Wind turbine gear box Grade 6, less than 0.8μm

4. Fully surrounded air will cool down the ring die and lower down the ash inside pellets.

5. No Bearing inside roller shell (underneath)

Unique patent design, save huge cost of grease and bearing and shorten the breakdown time

6. Innovated bearing system for pellet cutter low down the noise and vibration of pellet mill

7. Several Glass Viewing Window visualize the lubrication system inside the pellet mill.

8. 13 Years experience to develop biomass pellet mill.

9. Local team for after sales technical support.

10. Deploy new technology for production line and consumable parts.

11. Customized design and build

12. Hands on plant operation experience.

13. Monthly Capacity for our pellet mill is at least 30% higher than any other brands of pellet mill with sameoutput ofeletric motor (Energy is saved by 30%)

14. Monthly cost of spare parts (bearing/grease), since we do not have consumption of bearing and grease, the operational cost is only the ring die and roller shell oil seal, aramid packing, etc. Only 1/3-1/2 ofthe the other brands. (refer to the bar chart for consumption of bearing/ grease and service time of roller shell/die )

15. Monthly profit will be higher than other brands of pellet mill of same output.

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.