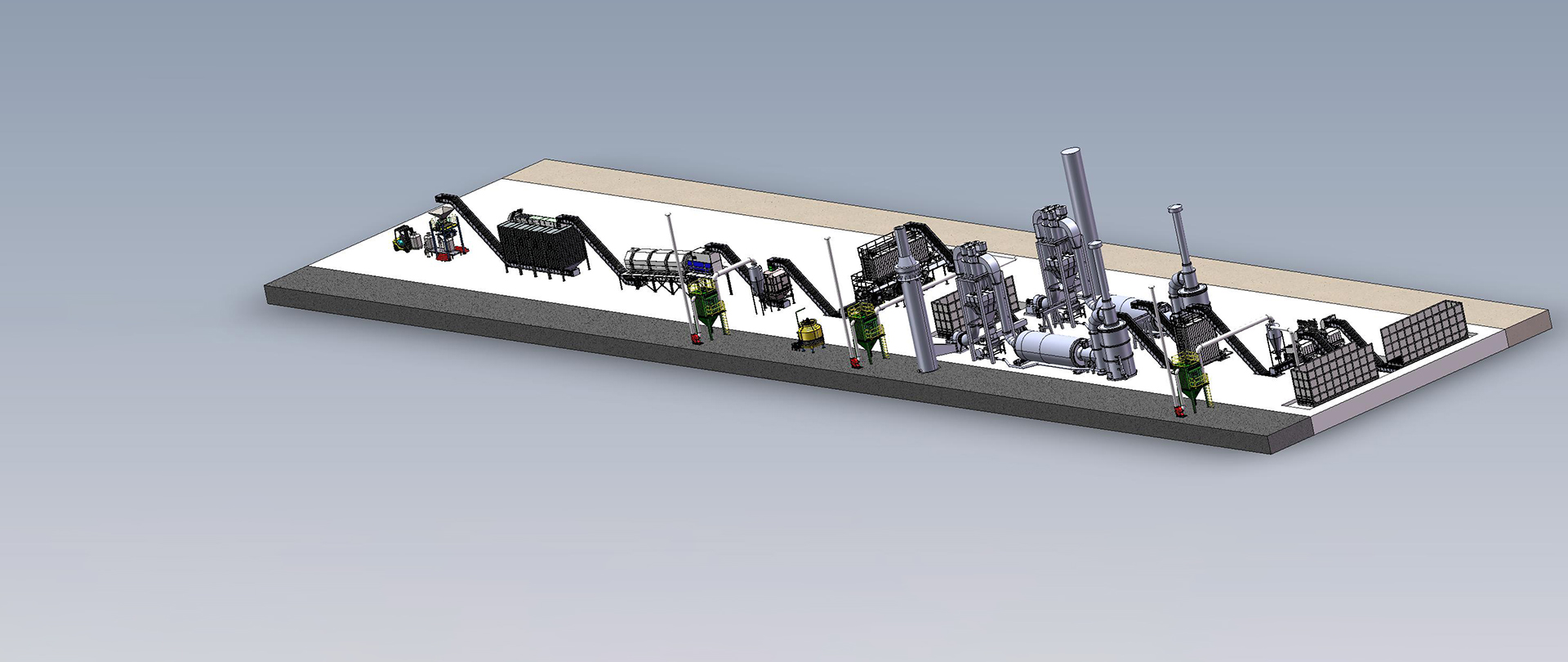

Biochar Pellets Production line

Biochar Pellets Production line

OPM offers the supply of turnkey plants for the production of biochar pellets

including the following steps:

· Mixer the biochar with moisture and industrial Starch.

· Pellet mill.

· Cooler for pelletizing chamber.

· Pellets Storage: loading system to truck, rail, wagon and navy.

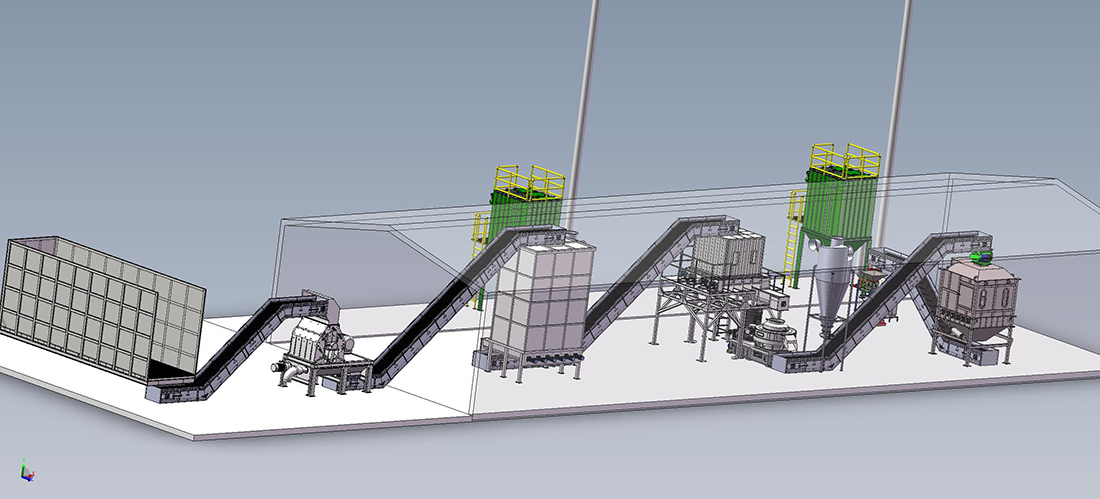

Equipment List

Technical Data Sheet

| Model OSK | OSK 75 | OSK220 | OSK315 | OSK510 | |

| Die | inside Diameter(mm) | 580 | 780 | 980 | 1250 |

| Capacity(T/H) | 0.8-1 | 3-4 | 5-6 | 9-11 | |

| Roller | Quantity | 3 | 3 | 4 | 6 |

| main motor | power(kw) | 75 | 220 | 315 | 510 |

| Feeder | motor(kw) | 1.5 | 2.2 | 3 | 5.5 |

| speed(rpm) | 500 | 500 | 500 | 500 | |

| outline dimension | mm | 2800x1200x1650 | 3200x1600x1800 | 3200x1700x2100 | 3530x1985x2075 |

| Weight | N.W | 4500kgs | 10000kg | 14390kgs | 21500kgs |

Main Features

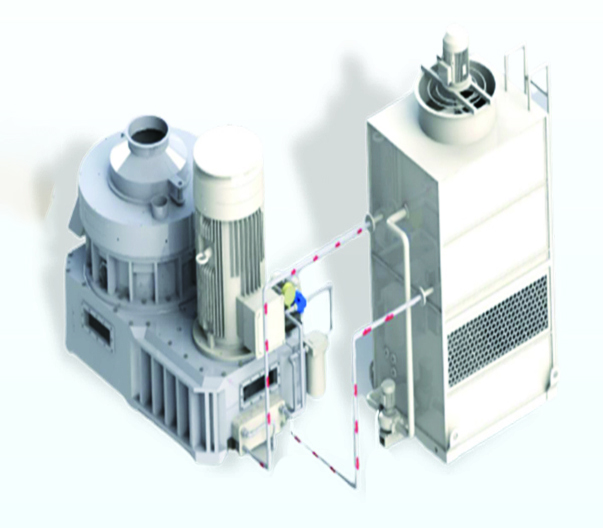

1. Low Speed of Electric motor

High Torque from low speed will make sure good quality of pellets

2. External Cooling Tower make sure the long operation time each day (occassionally, 24/7 will be acceptable. )

3. Helical Gear box

Std of Accuracy of CNC machining same as Wind turbine gear box Grade 6, less than 0.8μm

4. Fully surrounded air will cool down the ring die and lower down the ash inside pellets.

5. No Bearing inside roller shell (underneath)

Unique patent design, save huge cost of grease and bearing and shorten the breakdown time

6. Innovated bearing system for pellet cutter low down the noise and vibration of pellet mill

7. Several Glass Viewing Window visualize the lubrication system inside the pellet mill.

8. 13 Years experience to develop biomass pellet mill.

9. Local team for after sales technical support.

10. Deploy new technology for production line and consumable parts.

11. Customized design and build

12. Hands on plant operation experience.

13. Monthly Capacity for our pellet mill is at least 30% higher than any other brands of pellet mill with sameoutput ofeletric motor (Energy is saved by 30%)

14. Monthly cost of spare parts (bearing/grease), since we do not have consumption of bearing and grease, the operational cost is only the ring die and roller shell oil seal, aramid packing, etc. Only 1/3-1/2 ofthe the other brands. (refer to the bar chart for consumption of bearing/ grease and service time of roller shell/die )

15. Monthly profit will be higher than other brands of pellet mill of same output.

Sharing our professional team of engineers’ experience

We take your production to next level by improving plant efficiency and reduce downtime with advanced plant automation solutions.

We also design and build electrical control panel for safe area and hazardous area, site wiring and commission support.

Our experience covers most of leading brands of SCADA, PLC&HMI.

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.