Black Pellets production line

Black Pellets production line

(Steam Explosion technology-EFB and Woody Material)

OPM offers the supply of turnkey plants for the production of black pellets production line

including the following steps:

a. Wood Black Pellets Production line

· Chipper

· Hammer Mills .

· Steam Explosion reactor

· Single Pass Dryer

· Wood Pellet mills

b. EFB Black Pellets Production line

· Shredder

· Steam Explosion reactor

· Low temperature Single Pass Dryer or mesh dryer.

· EFB Pellet mills

Equipment List

Chipper

220KW 15-20T/H (Log <=30cm)

|

|

|

Rotor diameter |

1000mm |

|

Rotor Speed |

550rpm |

|

Capacity |

75m3/H |

|

Feeding size |

330mm*1050mm |

|

Number of rotor knives |

4*2 pcs |

|

Feeding Speed |

37m/min |

|

Main drive motor power |

220KW |

|

Feeding power(frequency) |

7.5KW+7.5KW |

|

Hydraulic oil pump motor |

2.2KW |

|

Finished Chip length(mm) |

15mm |

|

Outline Dimension (mm) |

9640x3500x1500mm |

Hammer Mill

|

Main drive motor power |

180KW |

|

Feeding Belt Conveyor |

4KW |

|

Capacity |

5-7t/h |

|

Hammer Qty |

100 |

|

Hammer Material |

High Mn Steel |

|

Hammer Life Time |

3-5 months |

|

Rotor Rotation |

2000 |

|

Static Knives |

4 PCS |

|

Cyclone |

1800MM |

|

Fan(Positive) |

18.5KW |

|

Dust Collector |

30 |

|

Air Lock(BF-650) |

3KW |

|

Output Belt Conveyor |

4KW |

|

Gross Weight |

5.6T |

|

Overall Dimension |

2500*2700*3100mm |

Drying System

SK-40 Three Pass Rotary Drum Dryer System

(Moisture of Dust:45% or less ,Final Moisture:15% roughly)

|

|

|

5-6T/H Three pass drum dryer

|

Include: |

The fee of engineers commission is USD250/day, the return ticket/accomodation will be paid by buyer. The wire tunnel and wire connected with power supply should be handled by end user The U/H type steel need to be prepared by end user for installation If simple water spraying for fire fighting is needed, the end user should purchase it locally.

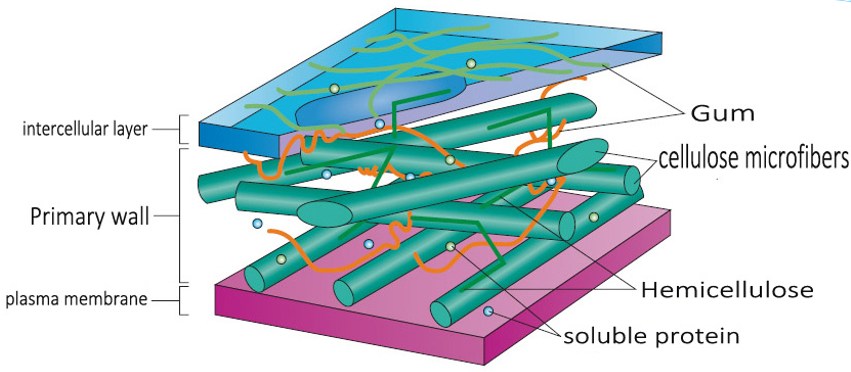

Biomass conversion barrier

* Conversion object: Organic cell body

* Barrier No.1: Three Layer Wrap for cell.

* Barrier No.2: crystal structure

* Other Barrier: cell wall, epidermis, waxy layer, etc

Schematic diagram of cell wall structure |

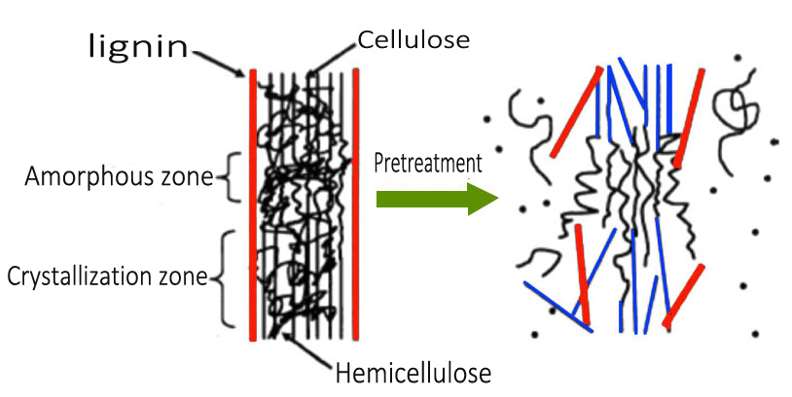

Pretreatment Mechanism

* Break the wall

* Three element separation

* Break down the structure

* Reduce crystallinity

* Increase porosity

* Improve accessibility

Schematic diagram of pretreatment mechanism |

Advantage

|

|

• Low Speed of Electric motor High Torque from low speed will make sure good quality of pellets • External Cooling Tower make sure the long operation time each day (occassionally, 24/7 will be acceptable. ) • Helical Gear box Std of Accuracy of CNC machining same as Wind turbine gear box Grade 6, less than 0.8μm • Fully surrounded air will cool down the ring die and lower down the ash inside pellets. • No Bearing inside roller shell (underneath) Unique patent design, save huge cost of grease and bearing and shorten the breakdown time • Innovated bearing system for pellet cutter low down the noise and vibration of pellet mill • Several Glass Viewing Window visualize the lubrication system inside the pellet mill. |

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.