Wood Pellets Production Line

Wood Pellets Production Line

OPM offers the supply of turnkey plants for the production of pellets including the following steps:

· Wood processing (debarking, chipping and rechipping)

· Storage, cleaning and dosing of the raw material

· Thermal drying

· Milling and pelleting line

· Pellets Storage: loading system to truck, rail, wagon and navy

Equipment List

Debarker(output77KW)

Heavy Duty Twin Shaft Debarker

|

|

|

|

Output(one section) |

30KW+7.5KW (Chinese famous brands of eletric motor) |

|

Reducer |

H series Gear Box (Harden Surface) (Chinese famous brand) |

|

Qty of Teeth |

96 pcs (25mm thickness) --Casting Material (Changable) |

|

Roller |

Seamless Pipe 12mm |

|

Outline Dimension |

5600x1950x2150mm |

|

Width of Groove |

1415mm |

|

Thickness of Steel |

20mm |

|

Bearing |

Chinese Heavy duty bearing |

|

Weight of each section |

9000kgs. |

Chipper

220KW 15-20T/H (Log <=30cm)

|

|

|

Rotor diameter |

1000mm |

|

Rotor Speed |

550rpm |

|

Capacity |

75m3/H |

|

Feeding size |

330mm*1050mm |

|

Number of rotor knives |

4*2 pcs |

|

Feeding Speed |

37m/min |

|

Main drive motor power |

220KW |

|

Feeding power(frequency) |

7.5KW+7.5KW |

|

Hydraulic oil pump motor |

2.2KW |

|

Finished Chip length(mm) |

15mm |

|

Outline Dimension (mm) |

9640x3500x1500mm |

Hammer Mill

|

Main drive motor power |

180KW |

|

Feeding Belt Conveyor |

4KW |

|

Capacity |

5-7t/h |

|

Hammer Qty |

100 |

|

Hammer Material |

High Mn Steel |

|

Hammer Life Time |

3-5 months |

|

Rotor Rotation |

2000 |

|

Static Knives |

4 PCS |

|

Cyclone |

1800MM |

|

Fan(Positive) |

18.5KW |

|

Dust Collector |

30 |

|

Air Lock(BF-650) |

3KW |

|

Output Belt Conveyor |

4KW |

|

Gross Weight |

5.6T |

|

Overall Dimension |

2500*2700*3100mm |

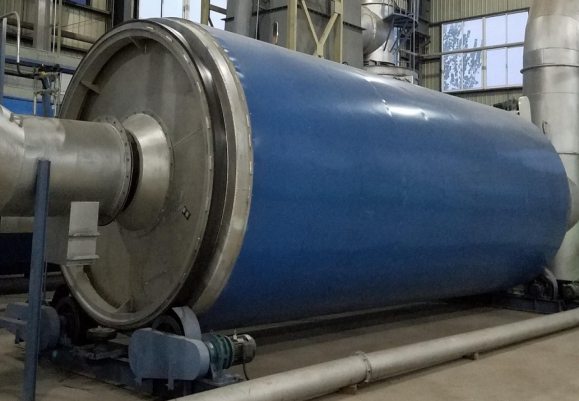

Drying System

SK-40 Three Pass Rotary Drum Dryer System

(Moisture of Dust:45% or less ,Final Moisture:15% roughly)

|

|

|

5-6T/H Three pass drum dryer

|

Include: |

The fee of engineers commission is USD250/day, the return ticket/accomodation will be paid by buyer. The wire tunnel and wire connected with power supply should be handled by end user The U/H type steel need to be prepared by end user for installation If simple water spraying for fire fighting is needed, the end user should purchase it locally.

Mesh type Pellet Cooling System

|

|

|

|

Jumbo Bag Filling System

|

|

|

Feeding speed |

200--2500kgs |

|

Bagging Speed |

One Bag 2-3 Minutes(from feeding to end of bagging) |

|

Accuracy of Bagging |

Static accuracy: 0.1% FA 01MLIII Operation Accuracy: 0.3% |

|

Air Resource |

0.4-0.6MPa. Consumption: 2m3/h |

|

Power Supply |

5.5KW 380V |

|

Vaccum Dust Collector: |

100-120mmHg Flow Rate:10-12m3/m |

|

Outline Dimension: |

1600x1600x2800mm |

Advantage

• Low Speed of Electric motor

High Torque from low speed will make sure good quality of pellets

• External Cooling Tower make sure the long operation time each day (occassionally, 24/7 will be acceptable. )

• Helical Gear box

Std of Accuracy of CNC machining same as Wind turbine gear box Grade 6, less than 0.8μm

• Fully surrounded air will cool down the ring die and lower down the ash inside pellets.

• No Bearing inside roller shell (underneath)

Unique patent design, save huge cost of grease and bearing and shorten the breakdown time

• Innovated bearing system for pellet cutter low down the noise and vibration of pellet mill

• Several Glass Viewing Window visualize the lubrication system inside the pellet mill.

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.