Pretreatment of mixed plastics for DOP plants

Pretreatment of mixed plastics for DOP plants

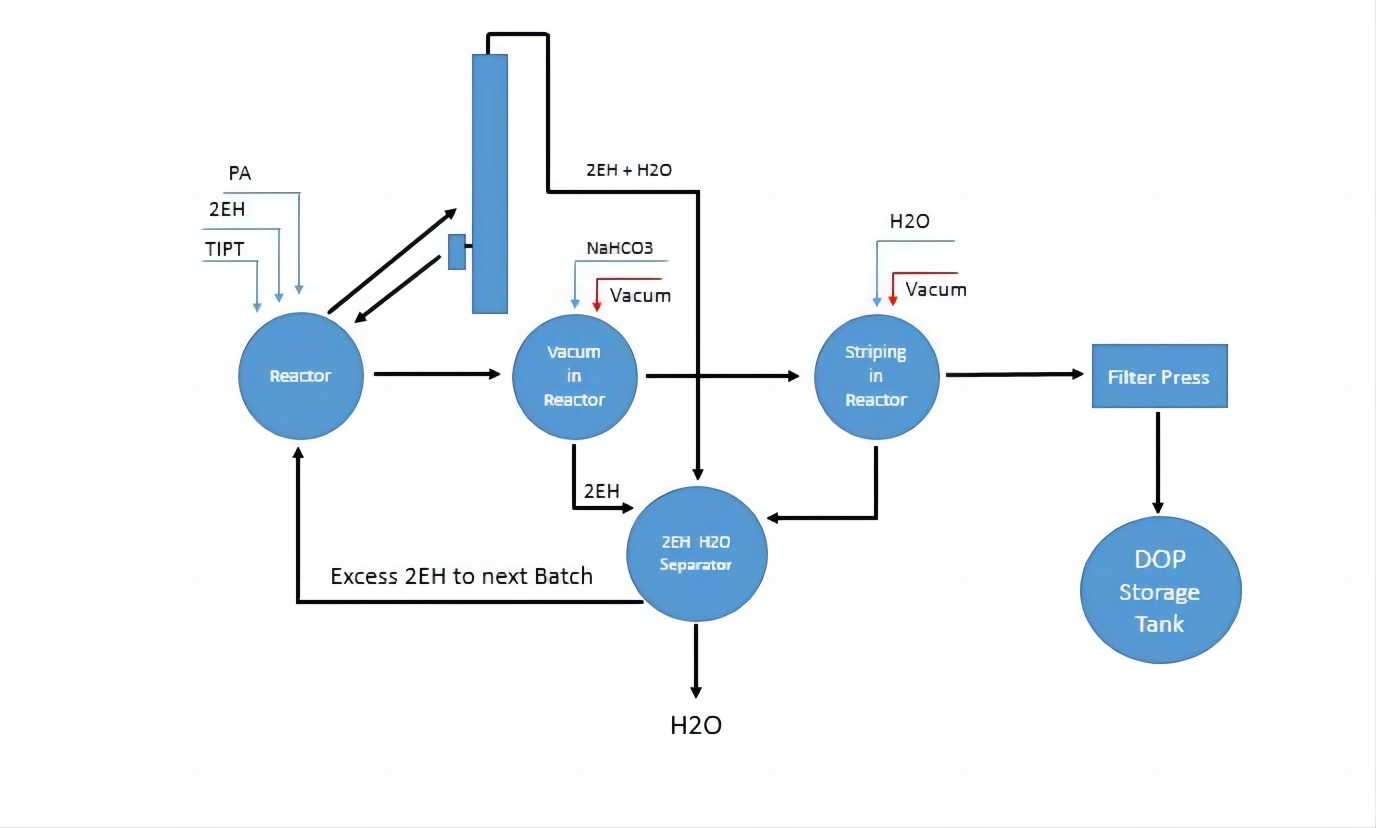

• To increase the efficiency of Reactor, raw material could be granulated(pelletized)

• The density of raw material can be Twice so efficiency of reactor can be double

Equipment List

Advantages of our Technology

| • Reaction temperature is maksimum 215 C • Reaction takes place in unpressurized, open to atmosphere platform. • Nitrogen gas is nonutilizable in the reaction. • The excess alcohol never turns to yellowish, even when it use a hundred times. • There is no alcohol lost or waste in production. • Manufactured DOP colour is always 20 hazen. • The mud amount resultant is %0,2 |

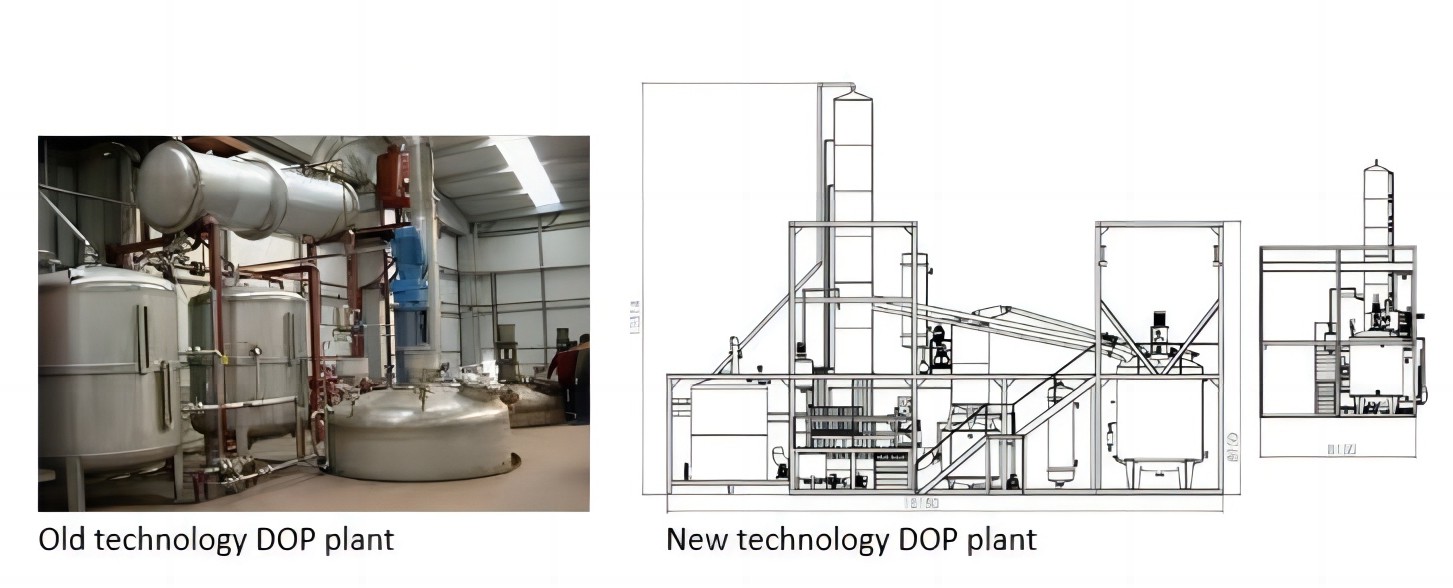

Turn-Key DOP plant

With our patented plasticizer technology, we build the most qualified and economic DOP (Di Octyl Phthalate) production plants. Through the advantages of our technology we have built 14 turn-key DOP plants in such a short time. The sum of the capacities of plans we built have reached to 350.000 tons/year.

Waste Materials from 1 Ton DOP Production

From DOP reaction 46 KG brilliant, light alcohol scented and residue free waste water comes out.

There is not any solid waste from DOP production. Only on the surface of the filter press there is around 1-2 mm DOP mug.

Flow-Chart of DOP

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.