Pretreatment of waste plastic for paper plants

Pretreatment of waste plastic for paper plants

OPM offers the supply of turnkey plants for the production of RPF pellets or briquettes including the following steps:

· Twin Shaft Shredder or four shaft shredder for RDF fluff.

· Magnetic Seperator to get rid of Metal inside.

· Dewatering Press to reduce the moisture of RDF inside

· Milling and pelletizing(briquetting) line

· Pellets Storage: loading system to truck, rail, wagon and navy

Equipment List

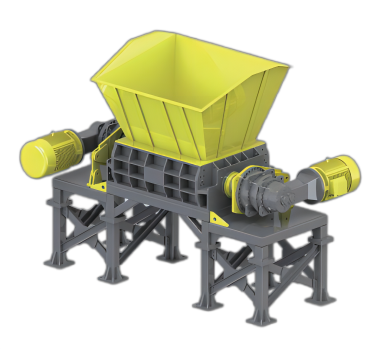

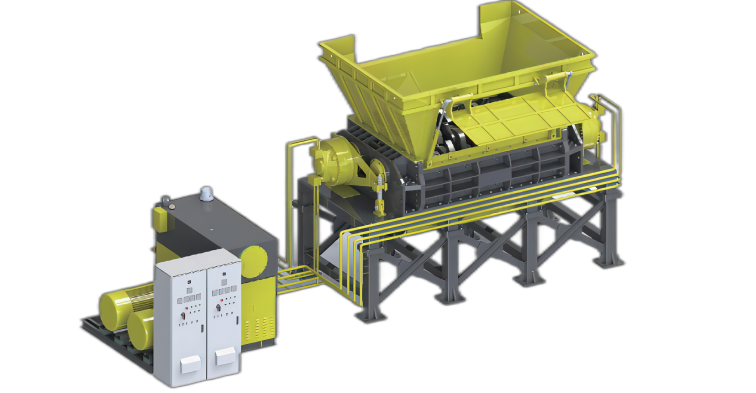

Double Shaft Shear Shredder

Double shaft shredder can be used for shredding most of wastes,such as the municipal solid waste,

wood waste,waste tyre, metal drum,plastic,RDF,biomass,etc. High capacity and high torque.

|

|

Application:

MSW shredding |

| Model | BEKEN-DS-2180 | BEKEN-DS-32120 | BEKEN-DS-40160 | BEKEN-DS-50180 | BEKEN-DS-61240 |

| A(mm) | 2760 | 2900 | 4180 | 5691 | 6400 |

| B(mm) | 1060 | 1850 | 2150 | 2160 | 2400 |

| C(mm) | 800 | 1200 | 1600 | 1800 | 2400 |

| D(mm) | 480 | 690 | 850 | 1120 | 1490 |

| H(mm) | 1850 | 2115 | 2530 | 3042 | 3330 |

| Cutter rotary diameter(mm) | φ284 | φ430 | φ514 | φ660 | φ800 |

| Shaft speed(rpm) | 14 | 15 | 11 | 23 | 7.5 |

| Cutter QTY(pcs) | 40 | 30 | 32 | 22 | 48 |

| Cutter thickness(mm) | 20 | 40 | 50 | 80 | 50 |

| Motor(KW) | 7.5+7.5 | 22+22 | 45+45 | 55+55 | 90+90 |

Advantage

|

|

• Low Speed of Electric motor High Torque from low speed will make sure good quality of pellets • External Cooling Tower make sure the long operation time each day (occassionally, 24/7 will be acceptable. ) • Helical Gear box Std of Accuracy of CNC machining same as Wind turbine gear box Grade 6, less than 0.8μm • Fully surrounded air will cool down the ring die and lower down the ash inside pellets. • No Bearing inside roller shell (underneath) Unique patent design, save huge cost of grease and bearing and shorten the breakdown time • Innovated bearing system for pellet cutter low down the noise and vibration of pellet mill • Several Glass Viewing Window visualize the lubrication system inside the pellet mill. |

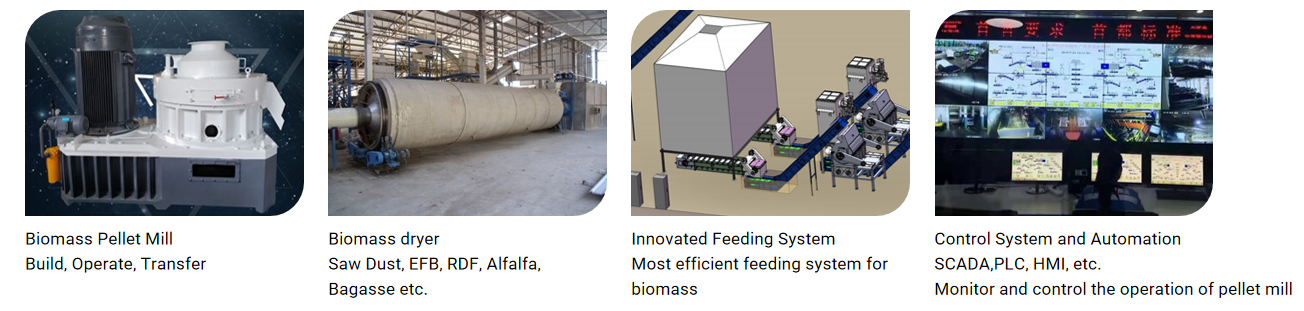

Easy the biomass pellets production line

Best Innovated Pellet Mill

Over 13 years of biomass pellet mills production.

We provide consultation, design, fabrication, installation, testing, commissioning, training, and local service team 24/7 hours standby.

Sharing our professional team of engineers’ experience

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.