Sludge Pellets Production line

Sludge Pellets Production line

OPM offers the supply of turnkey plants for the production of Sludge pellets

including the following steps:

· MDS multi-disc Screw Press (or Filter Press)

· Low Temperature Mesh Dryer for sludge drying

· Hammer mills for sludge

· Sludge Pellet mills

· Sludge pellets Gasifier for CHP application

Equipment List

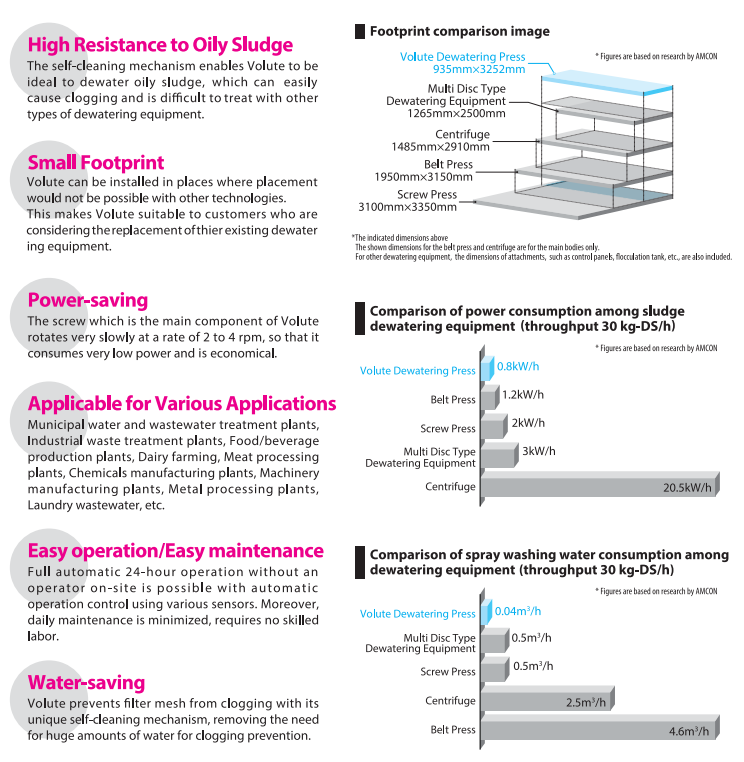

Advantages of Volute

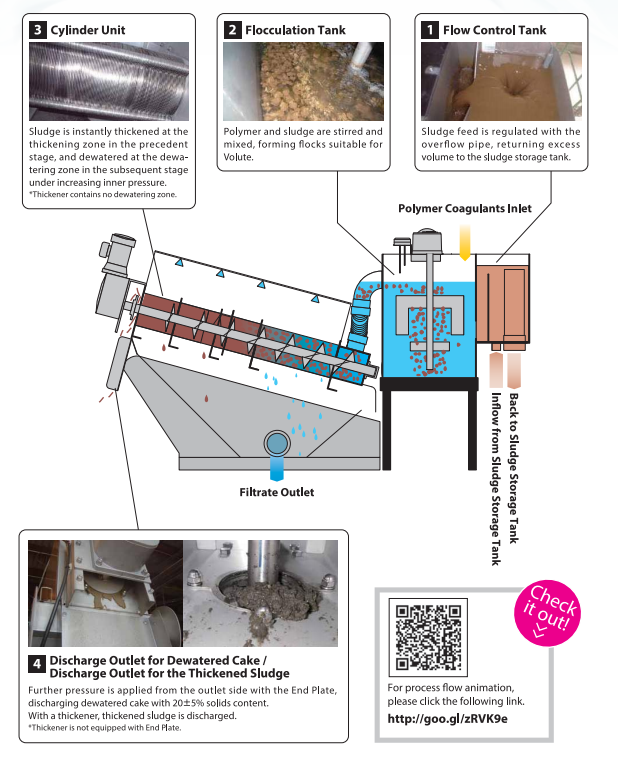

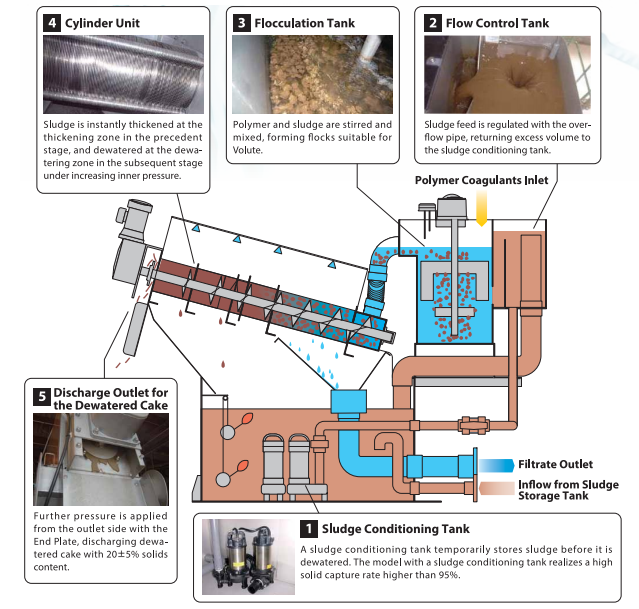

Process Flow

Model without sludge conditioning tank

Model with sludge conditioning tank

Enclosed waste heat filter cake dryer

product feature:

cake≤ 10% moisture content, The material can be reduced by more than 80%.

Heat is 100 per cent without thermal damage.

No deodorant, no stinking emissions.

Stable and durable, modular design.

Thermal heat source design, operating cost is low to 50kw. H/T.

Low temperature operation, safe and reliable, no dust and explosion hazard.

|

model |

JJYR5000 |

JJYR10000 |

JJYR15000 |

JJYR20000 |

JJYR25000 |

|

Standard water displacement/24h |

5000kg |

10000kg |

15000kg |

20000kg |

25000kg |

|

Water displacement/h |

208kg |

416kg |

624 kg |

832 kg |

1040 kg |

|

Operate power/h |

13kw |

26kw |

39kw |

52kw |

65kw |

|

Dry module |

1pcs |

2pcs |

3pcs |

4pcs |

5pcs |

|

Power supply |

220V/380V/440V 3H 50HZ/60HZ |

||||

|

heat source |

Generator waste heat, steam condensate, Gas-fired hot water, fume waste heat,( heat transfer) etc. |

||||

|

Control system |

Programmable Logic Controller+ touching screen |

||||

|

Applicable range of wet mud |

40%-83%moisture content(material with different moisture content has different adaptation ) |

||||

|

Dry material moisture content |

variable frequency regulation(5%-60%) The cake moisture can be adjusted to be different according to the feeding material moisture content |

||||

|

Molding method |

cut into strips /squeezing into strips etc.(choose according to the different material) |

||||

|

overall dimension |

4770x3135x3260 |

8020x3135x3260 |

11270x3135x3260 |

14520x3135x3260 |

17770x3135x3260 |

|

structural style |

assemble |

assemble |

assemble |

assemble |

assemble |

|

model |

JJYR30000 |

JJYR35000 |

JJYR40000 |

JJYR45000 |

JJYR50000 |

|

Standard water displacement/24h |

30000kg |

35000kg |

40000kg |

45000kg |

50000kg |

|

Water displacement/h |

1248kg |

1458kg |

1667kg |

1875kg |

2083kg |

|

Operate power/h |

78kw |

91kw |

104kw |

117kw |

130kw |

|

Dry module |

6pcs |

7pcs |

8pcs |

9pcs |

10pcs |

|

Power supply |

220V/380V/440V 3H 50HZ/60HZ |

||||

|

Heat source |

Generator waste heat, steam condensate, Gas-fired hot water, fume waste heat,( heat transfer) etc. |

||||

|

Control system |

Programmable Logic Controller+ touching screen |

||||

|

Wet mud application range |

40%-83%moisture content(material with different moisture content has different adaptation ) |

||||

|

Dry material moisture content |

variable frequency regulation(5%-60%) The cake moisture can be adjusted to be different according to the feeding material moisture content |

||||

|

Molding method |

cut into strips /squeezing into strips etc.(choose according to the different material) |

||||

|

Overall dimension |

21020x3135x3260 |

24270x3135x3260 |

27520x3135x3260 |

30770x3135x3260 |

34020x3135x3260 |

|

structural style |

assemble |

assemble |

assemble |

assemble |

assemble |

Volute Sludge Dewatering Press Userr Manuall

|

Safety Instructions

● Before using the product, be sure to read it thoroughly and fully understand this manual

so that it can be used safely. |

Forward Thank you very much for choosing our company's products. Volute dewatering machine adopts multi-overlapping spiral screw filter method, saves water and electricity, and is durable; it creates a precedent for direct dewatering of low-concentration sludge, and achieves breakthrough of 24 hours continuous unmanned operation; greatly reduces the cost of design, construction operation and maintenance, is a new type of highly efficient sludge dewatering machine. To enable you to skillfully operate the dehydrator and maximize its superior performance, please read and fully understand this manual and related technical data before using it. |

|

Warning

● Do not use in an explosive environment. Do not use in an explosive environment. |

|

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.