EFB briquettes production line for CPO mills

EFB briquettes production line for CPO mills

OPM offers the supply of turnkey plants for the production of EFB briquettes production line for CPO mills including the following steps:

· Shredder

· Low temperature mesh dryer or single pass dryer

· EFB pellets (briquettes) machine

Equipment List

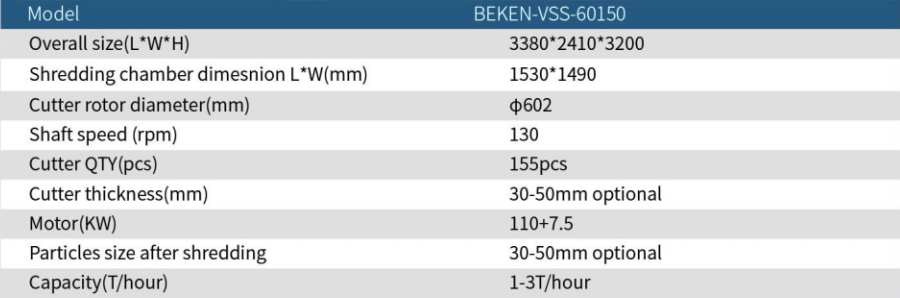

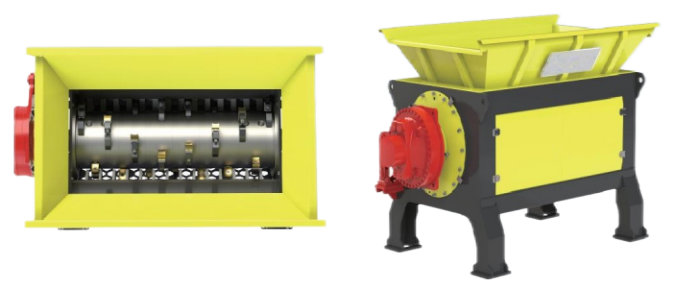

Single Shaft Shredder (Rdf Shredder)

|

Vertical single Shaft Shredder(With double pusher)

Easy to change the cutters |

Application:

RDF(Waste plastic,biomass, wood,rubber,leather,paper, fabric,fiber,etc.) |

|

|

|

|

|

Vertical Single Shaft Shredder(No pusher)

Suit for biomass shredding |

Application:

Biomass RDF(Waste plastic,biomass, wood, rubber, leather, paper, fabric, fiber, etc.) |

|

|

|

|

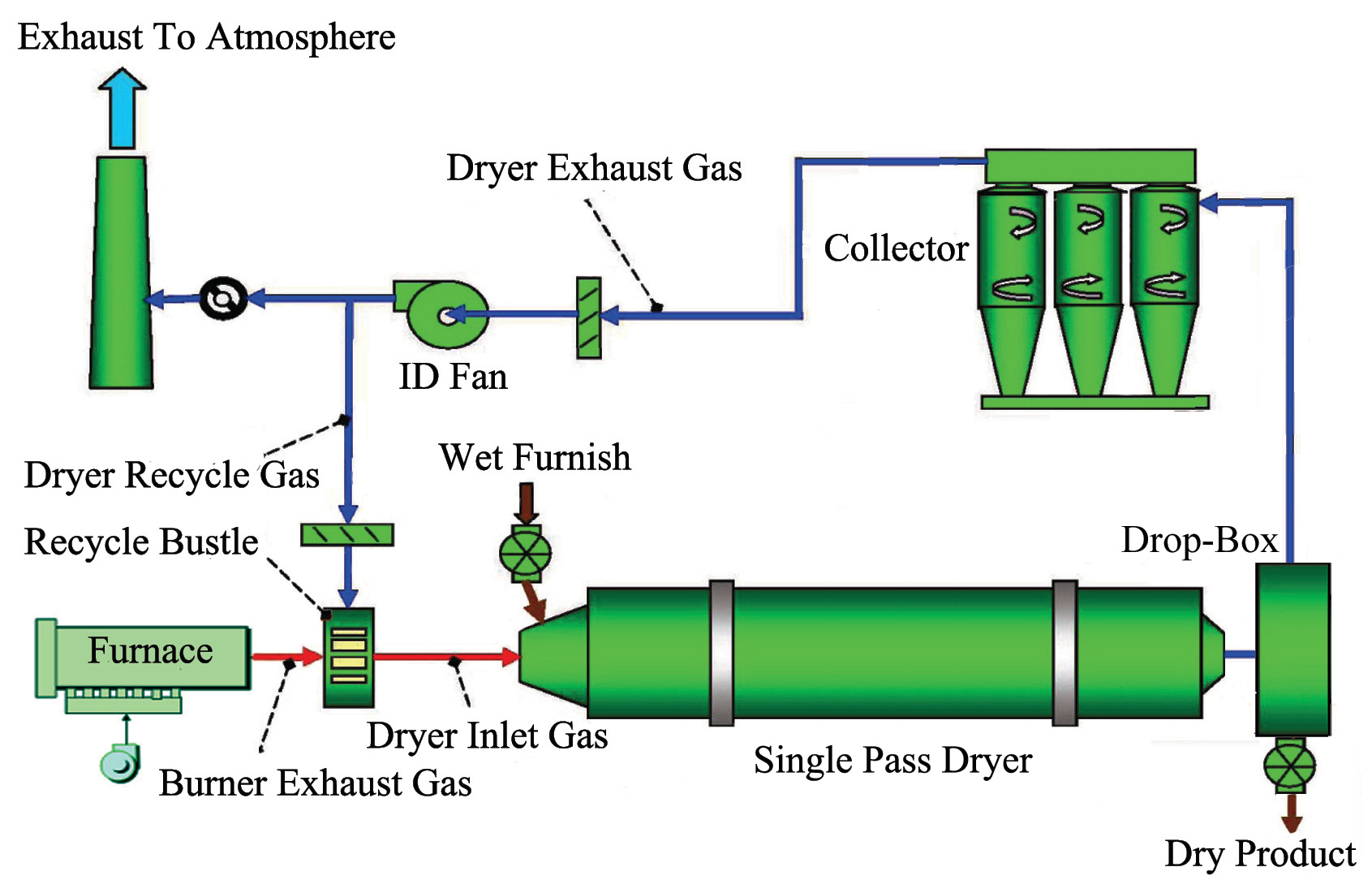

Process Flowchart

In single pass dryer, wet furnish is mixed directly with hot gas inside the rotating insulated drum. The wet materials and hot gas normally flow concurrently through the dryer so the hottest gases come in contact with the wettest material.

The product is dried with hot gas at 350 ºC approx. in the rotary drum. The rotary drum is divided into different sections for a higher efficiency in the execution of the dehydration. In the first contact between the vapor and the product, a spontaneous evaporation is produced resulting in a temperature drop to 150-180 ºC. Immediately after, a slow and progressive drying takes place until reaching a temperature of 95-110 ºC at the outlet of rotary drum.

The rotation of the drum, with the aid of flights, lifts solids in the dryer so they tumble through the hot gas, promoting better heat and mass transfer. Hot flue gas can be fed directly into the dryer. Other options include using a burner or a steam heater to raise the temperature of incoming air.

The exhaust gases leaving the dryer may pass through a cyclone, multi-cyclone, baghouse filter, scrubber, ESP or WESP to remove any fine material entrained in the gas. An ID fan is usually placed after the emissions control equipment to reduce erosion of the fan, but may also be placed before the first cyclone to provide the pressure drop through downstream equipment.

|

|

|

|

Sharing our professional team of engineers’ experience

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.