Three Pass Dryer

Three Pass Dryer

Three pass rotary dryer can be used for saw dust,wood chips,straw,wood sheaving, Medicago sativa, Cassava, Distillers' grains, herb,etc

The dryer use the furnace that has different stages, the efficiency for the heating is rising up 15%-20%, and the cost to dry is lowered down, the tense of the drying is 2 or 3 times than traditional dryer, and the length of the drum is 30%-40% shorter than the single pass, the occupation of the three pass dryer is 65% lower than the single pass dryer.

Equipment List

Three pass rotary dryer

| Three pass rotary dryer can be used for saw dust,wood chips,straw,wood sheaving, Medicago sativa, Cassava, Distillers' grains, herb,etc The dryer use the furnace that has different stages, the efficiency for the heating is rising up 15%-20%, and the cost to dry is lowered down, the tense of the drying is 2 or 3 times than traditional dryer, and the length of the drum is 30%-40% shorter than the single pass, the occupation of the three pass dryer is 65% lower than the single pass dryer. |  |

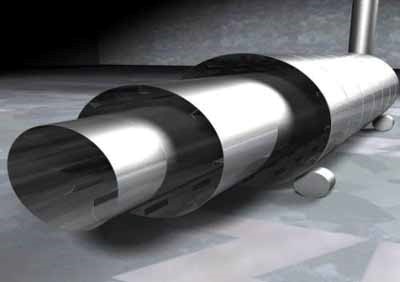

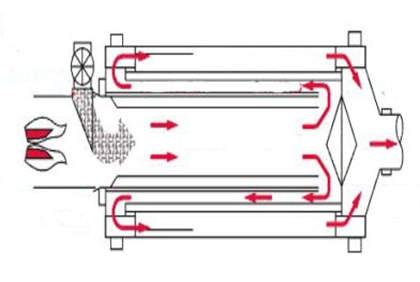

1. Philosophy for the three pass dryer

Three pass dryer is composed of three drum, the material flow as follows: Inner drum-->middle drum--->outter drum, every drum has the special shape of material guiding plate, the material is moved by the rotary force from drum and the attrative force from hot air.

|  |

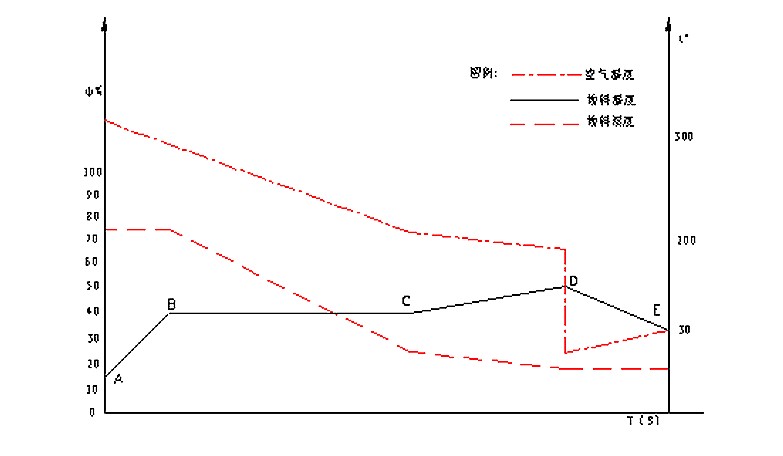

2. The working status for dryer:

| AB: pre-heating stage, material is transfered to the dryer, since the hot air, the temperature of material is rising up the wet ball, at this stage, the moisture inside the material is stable, and the temperature of hot air is dropping down, the heat release from hot air is use to pre heat the wet material. BC. drying at the same speed, the ratio of drying is stable, at this stage, the feasture of wet ball has free water to be evapourated by the heat transfered from the hot air so that the temperature is stable, but the temperature of hot air and the moisture of material is dropping down. CD: The ratio of drying is dropping down, the spreading ratio of moisture inside the material is less than Rate of Evaporation for the moisture, the surface of material do not have enough moisture, so the ratio of drying is slow down, the heat transferd to the material is high than the heat used to evaporate the moisture so that the temperature of material is rising up and the temperature of hot air is dropping down. DE, The moisture of material is lowered down the request and the material is released from the dryer to cooling system to make sure the temperature of material is a little high than ambient and pack it up. |

3. specification of three pass dryer:

| Heat Exchange——Agent for drying is hot air | |||||||||||||||

| Model | HTG-600 | HTG-1200 | HTG-2400 | HTG-4800 | HTG-8000 | ||||||||||

| Moisture erase | 600 | 1200 | 2400 | 4800 | 8000 | ||||||||||

| Primary moisture | 70% | 60% | 50% | 70% | 60% | 50% | 70% | 60% | 50% | 70% | 60% | 50% | 70% | 60% | 50% |

| Final moisture | 10% | 10% | 10% | 10% | 10% | ||||||||||

| Capacity(dryed) | 300--800 | 600--1500 | 1200--3000 | 2400--6000 | 4000--10000 | ||||||||||

| kgs/h | |||||||||||||||

| Coal consumption | 500 | 320 | 240 | 500 | 320 | 240 | 500 | 320 | 240 | 500 | 320 | 240 | 500 | 320 | 240 |

| Kgs/t | |||||||||||||||

| Electricity consumption | 37 | 72.1 | 98.7 | 131,6 | 168 | ||||||||||

| Output | 45 | 95 | 130 | 175 | 220 | ||||||||||

| Outter dimension(m) | 32*6*5 | 34*7*6 | 36*9*7 | 38*10*7 | 50*10*8 | ||||||||||

| Area | 500 | 500 | 600 | 600 | 800 | ||||||||||

Direct Heating ——agent is high

temperature cleaned bluegas

| Model | HTG-900 | HTG-1800 | HTG-3600 | HTG-4800 | HTG-5400 | HTG-8000 | ||||||||||||

| Moisture erase | 900 | 1800 | 3600 | 4800 | 5400 | 8000 | ||||||||||||

| Primary moisture | 70% | 60% | 50% | 70% | 60% | 50% | 70% | 60% | 50% | 70% | 60% | 50% | 70% | 60% | 50% | 70% | 60% | 50% |

| Final moisture | 10% | 10% | 10% | 10% | 10% | 10% | ||||||||||||

| Capacity(dryed) | 300--800 | 600--1500 | 1200--3000 | 2400--6000 | 2700-6000 | 4000-10000 | ||||||||||||

| kgs/h | ||||||||||||||||||

| Electricity consumption | 25 | 38 | 53 | 60 | 75 | 105 | ||||||||||||

| Coal consumption | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 |

| Kgs/t | ||||||||||||||||||

| Output | 37 | 54 | 75 | 110 | 128 | 150 | ||||||||||||

| Outter dimension M | 24×6×5 | 26×8×7 | 30×9×8 | 32×10×9 | 36×12×10 | 40×12×12 | ||||||||||||

| Item | Reference 1 | Reference 2 |

| Material dried | Wood sheaving | Wood chips |

| kg/h | 8000 | 2500 |

| Inlet hot air℃ | 550-600 | 360-400 |

| Outlet hot air℃ | 110-125 | 130 |

| Speed of drum rpm | 5.5 | 5.5 |

| Introduction fan kw | 125 | 55 |

| Output for dryer kw | 13 | 8 |

| Air capacity m3/h | 60000 | 27000 |

| Lenght of drier m | 10 | 9 |

| Diameter of dryer m | 3.4 | 2.2 |

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.